Marine engineering company, Royal Roos is on a mission with Royal3D printing, in an effort to make the maritime sector more sustainable.

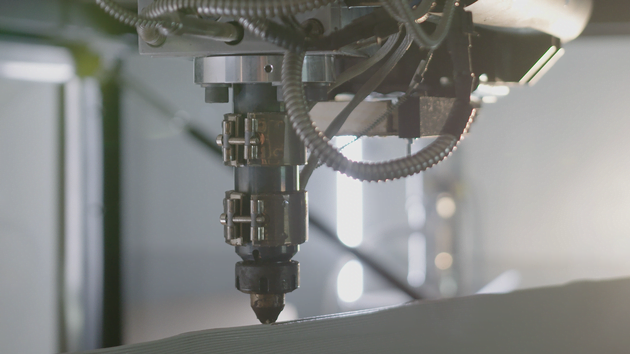

Royal Roos, which focuses on designing ships, maritime constructions and conversions and repairs, launched the Royal3D printer in order to revolutionise the maritime industry.

“The items we are currently printing represent important intermediate steps. Soon we will be printing workboats, for example, for the boatmen in the Port of Rotterdam. Big plans, but we also have a big printer.”

Until recently, printing a ships was unthinkable. But technology is developing at a rapid pace. According to the company, with its printer, it can now quickly and accurately print ships and parts that are strong enough. The ‘base material’ for the prints is plastic, and some of it comes from plastic waste.

The advantage of printing is that there is less residual material, and the material can be recycled and reused. Currently, they are only printing pleasure boats until they can also print real, large ships.

We are still working with Royal3D to optimise the process. Many materials still deform, which is why we still use expensive printing materials that don’t deform too much. We want to develop materials that do not deform and are also affordable. Of course, sometimes things do go wrong in the printing process. We put the misfits in the shredder to produce material that we can add to the printing material.

…Fulko Roos adds.

Concluding, Royal3D has discovered a good partner in the Port of Rotterdam Authority. “Our vision fits well with the Port Authority’s long-term vision. We both strive for progress, in a sustainable manner. We are happy to be here, right by the water where we can develop and test. It is a great collaboration, for example we are now investigating the possibilities of making products and printing materials from plastic waste from the port.”