Petar Modev, Loss Prevention Executive at UK P&I Club, examines common mooring practices and highlights the relevant actions to take to reduce the risk of accidents.

“Mooring equipment on vessels inspected during the study was often found to be in an acceptable state, particularly the overall condition of the mooring winches. However, it is important that all greasing points are free, working correctly and have not been painted over, to ensure that equipment can be greased to the suitable standard. It was also found that in a number of vessels the split drums were not set up correctly, with mooring being kept on the drum ends instead of making them fast, a practice which should be avoided, as ropes made fast on drum ends are more likely to jump and cause expensive damage.

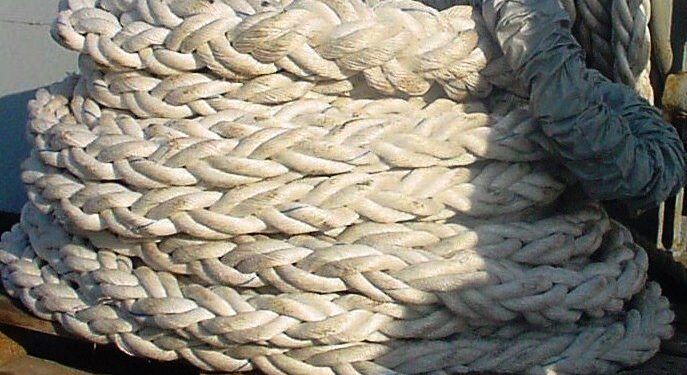

“It was found that the majority of ropes used aboard ship were in good condition, with over 250 of the 373 vessels inspected not using spliced ropes. Where ropes are in poor or damaged condition, they should be replaced with spares. It is important that all ropes, wires and Tonsberg links used for mooring have a certificate, and it is good practice for these certificates to be clearly labelled and kept in an easily accessible file ready for inspection by Port Authorities. Spare mooring ropes, wires and links should not be stowed with paint, chemicals, or any other shipboard or general cleaning items.

“The Club has seen a growing number of incidents occur when non-deck crew are used during mooring operations. It is important to have sufficient personnel to be able to moor the vessel safely and effectively, and all crew should be trained and be familiar with bights, snap-back zones and the hazards associated with mooring operations.

“It is vital that time is taken to ensure that procedures are not only acceptable but that they are followed by the crew. A number of familiar factors reoccur in mooring incidents: seafarers stand in bights or snap-back zones, and when ropes part those involved are often injured. When crew with insufficient training are used during mooring operations, it is often these people who are seriously injured if something goes wrong. The person supervising mooring is also involved with operations and is unable to carry out their role effectively.

“To reduce the risk of mooring accidents, the vessel and equipment must be maintained to a high standard, all personnel should be adequately trained with the correct personal protective equipment, the correct procedures should be in place, work permits issued and all mooring operations should be supervised by a competent person. Training in mooring operations should be incorporated into the vessels regular training schedule and include all personnel who are to be involved.

“Whilst mooring injuries are the seventh most frequent cause of personal injuries in the Club they are the third most expensive per claim, indicating how serious some of these injuries can be, and highlighting the importance of taking proper safety measures.”

Also read related article UK P&I Club to focus on Moorings

Source: The UK P&I Club