Rystad Energy predicts that by 2035, 174 export terminals will primarily focus on converting hydrogen into ammonia, accounting for 62% of total exported volumes, or about 13.5 million tonnes per annum (tpa).

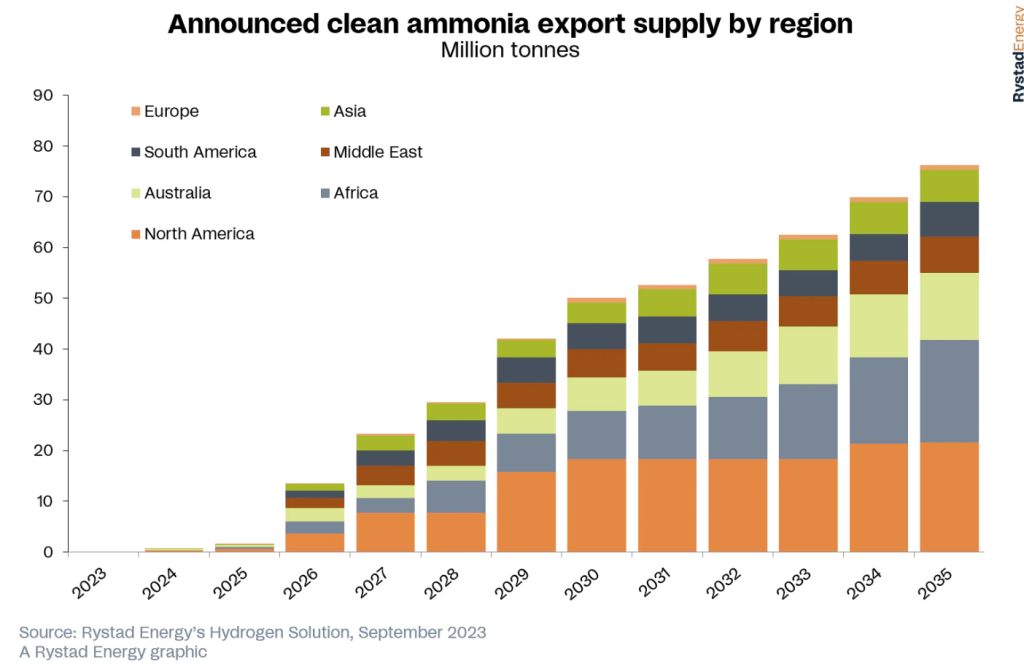

According to Rystad, a substantial upsurge in clean ammonia transportation and trade is anticipated, with traded volumes of ammonia projected to reach 76 million tonnes by 2035, four times the volume transported and traded in 2020. There are currently 220 ammonia infrastructure projects globally, with a combined handling capacity of more than 6 million tonnes

This surge, primarily originating from Africa and North America, will lead to a five-fold increase in ammonia exports by 2050 to 121 million tonnes.

Rystad’s estimates show global clean ammonia exports are set to surge to 121 million tpa by 2050, with Africa contributing 40.7 million tpa and Australia with 35.9 million tpa based on announced projects.

Australia, which is aspiring to be a top clean ammonia exporter, presently has just seven terminals with total storage capacity of approximately 173,000 tonnes. Without substantial expansion by 2040, this would be capable of accommodating just two to three days of planned clean ammonia exports.

To handle Australia’s projected monthly exports of ammonia, terminal capacity will need to increase ten-fold.

To handle Australia’s projected monthly exports of ammonia, terminal capacity will need to increase ten-fold.

Governments hold the key to action

Although the hydrogen economy is still in its early stages of development, demand for ammonia is already on-track to outpace available infrastructure. Both private and public sectors support the development of a global hydrogen economy, with major companies signing agreements with ammonia producers and governments auctioning off import contracts.

On the governmental front, auctions aimed at sourcing ammonia imports are gaining popularity. For instance, Germany’s H2Global auction, backed by €900 million ($978 million) in governmental support, will be the first of its kind globally and offer 10-year purchase agreements for green ammonia.

Additionally, various government-backed initiatives are geared towards creating fresh demand for ammonia, including its use as an alternative fuel in the maritime sector (supported by the FuelEU Maritime initiative) and co-firing applications in Japan.

Industry experts are already exploring the technical feasibility of these transitions, especially considering the projected rise in ammonia utilization for power generation and shipping.

Industry experts are already exploring the technical feasibility of these transitions, especially considering the projected rise in ammonia utilization for power generation and shipping.

Rystad estimates that switching LNG export and import facilities to ammonia would incur estimated costs ranging from 11% to 20% of the total LNG terminal capital expenditure, depending on factors such as demand and location.

Shipping industry growth and transition opportunities for LPG carriers

While still in its early stages, the ammonia shipping industry is expanding swiftly. Currently, just 30% of the global liquefied petroleum gas (LPG) fleet can transport ammonia, with only 50 large and very large gas carriers having this capability.

To meet rising demand, Eastern Pacific Shipping has commissioned four very large ammonia carriers (VLACs) from Jiangnan Shipbuilding Group. These VLACs will become the world’s largest carriers, each boasting 93,000 cubic meters of capacity.

To transport the announced 121 million tonnes of ammonia, approximately 200 VLACs will be required, necessitating an investment of approximately $20 billion in newbuilds. Beyond newbuilds, interest is growing in retrofitting LPG vessels for ammonia carriage.

Given the availability of over 1,450 LPG carriers, converting these vessels into ammonia-ready carriers offers a robust transition strategy for shipowners, particularly as demand for LPG tonne-mileage is anticipated to decline amid decarbonization efforts.

Converting LNG terminals could be a good solution, not only optimizing current infrastructure but also spurring a re-evaluation of strategies that can cope with the scale of the expected market expansion

… said Minh Khoi Le, Head of Hydrogen Research, Rystad Energy