The Nautical Institute presents an incident where, a tanker had berthed for discharge operations and had also ordered bunkers.

A bunker barge arrived at about 2:15 in the morning and was secured on the port side of the tanker. The bunker hose, supplied by the bunker barge, was connected to the tanker’s bunker manifold and surveyed to the extent possible by the tanker crew. Everything appeared correct and bunkering commenced with an initial rate of 40 tonnes/hr.

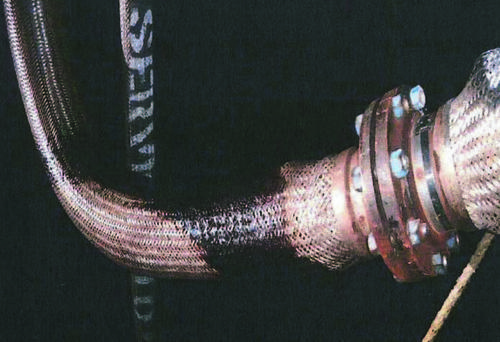

The bunkering station reported normal operations and no leaks so the rate was gradually increased to 180 tonnes/hr. Soon after the rate increase, a minor leak was observed in the hose and the bunkering was stopped. A small quantity of oil had spread on deck and was cleaned. No oil was seen to be released into the sea.

The bunker hose had apparently been tested under pressure four months earlier but was now clearly less than adequate for the job.

Lessons learned

- Visual inspection of a bunker hose before use is necessary but cannot guarantee the integrity of the hose under full operating pressure.

- Vigilance at the bunkering station is a primary defence against pollution. When bunkering in darkness, ensure the hose is well lit and visible along its entire length.