BSEE informs of an incident where a third-party contract operator sandblasting on an offshore facility in the Gulf of Mexico was injured when a temporary air dryer used for sandblasting operations recoiled and broke the safety cable, to provide lessons learned.

The incident

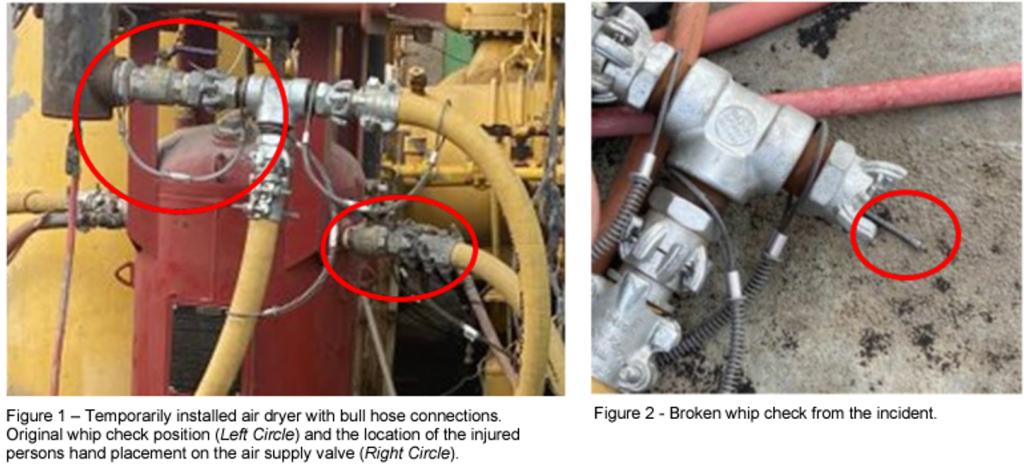

A worker was refilling the sand pot with an abrasive material to continue sandblasting operations. After confirming the air supply valve from the temporary air dryer to the sand pot was shut-in, the worker attempted to disconnect the air supply valve from the air dryer. As the worker tried to access this coupling, he loosened the T-connection. The Tconnection blew off and broke the braided steel cable designed to suppress the hose recoil when a pressurized release occurs. The whip check ends were looped between the hose and the coupling connection. The T-connection and broken whip check caused multiple cuts and abrasions to the worker’s head and shoulders.

BSEE inspectors identified the following contributing factors:

- The baling wire involved in the incident was slightly corroded, potentially diminishing its overall integrity. Baling wire is used as an additional safety measure to ensure couplings are securely connected. It is often used in place of a cotter pin on crowfoot couplings;

- The failed whip check cable was improperly crimped. Crimping the whip check cable before placing it into service allows it to function correctly at its full rated capacity.

- The bull hose configuration on the air inlet valve from the platform air compressor was installed in a horizontal position. This added weight caused the T-connection to be off-centre at the time of operation, adding stress on the associated couplings and baling wire. The added weight, combined with the worker’s force when manipulating the air supply valve to the sand pot, resulted in air escaping the inlet valve from the platform compressor, likely causing the connection to come loose.

Therefore, BSEE recommends that operators and contractors do the following:

- Conduct a pre-job hazard assessment with all affected personnel, including facility leadership, to confirm all aspects and associated mitigations of the task

are understood. - Install stainless steel tie wires in addition to whip checks on bull hoses to reduce the risk of disconnection.

- Install 90-degree fittings (Figure 4) to eliminate the horizontal orientation of the supply hose, reducing the stress at each connection

- Depressurize equipment prior to adjusting valves when practical.

- Inspect all equipment and parts pre-job to ensure they are in adequate condition.