BSEE (United States Bureau of Safety and Environmental Enforcement) informs of an incident where, a 700-pound crane headache ball fell 24 feet, while conducting crane operations during a decommissioning/well abandonment activity.

The incident

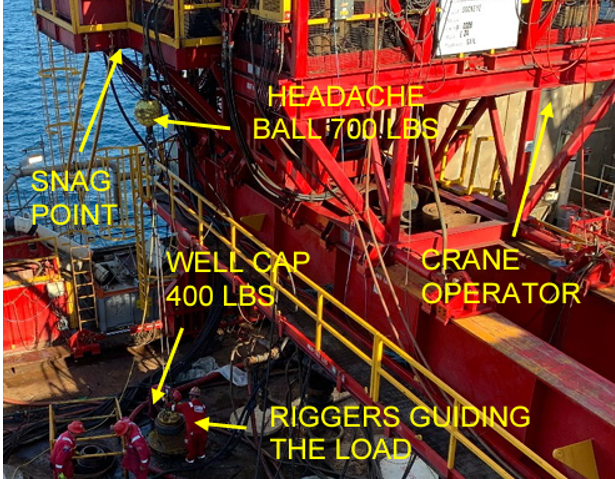

A crane was moving a 400-pound well cap from one well access panel to an adjacent panel when a wedge socket on the auxiliary line snagged on the flange of a C-channel located at the edge of the platform’s rig deck.

The lift required running the crane’s auxiliary line within inches of the edge of the platform rig structure. the wedge socket above the headache ball snagging on the C-channel flange that ran across the length of the edge of the deck. This snag temporarily held all the weight of the load and rigging, resulting in a false reading on the auxiliary winch. The load cell sending a weight signal to the operator was located below the snagged wedge socket. The crane operator did not detect that the auxiliary winch was no longer holding the weight of the load.

The rigger did not realize that the line had snagged on the C-channel and continued giving directions to keep lowering the well cap. As the load cell (which

work by converting a specific type of mechanical force — typically tension, torque, compression, or pressure — into an output signal. This output signal is then transmitted via a load cable to the scale’s indicator where the precise weight can be measured and read by the crane operator) was positioned below the snag, there was no change in the load signal, even though the weight of the load was now being supported by the C-channel and not the auxiliary winch.

The rigger, not seeing any movement, repeated a request to lower the load. Because the crane operator could not see the winch drum behind the crane cab,

he did not see that the load was not moving and responded that he was still lowering the load. As the crane operator continued to unwind the auxiliary line at the winch drum, the wedge socket slipped off the flange of the C-channel, releasing the snag. The 700-pound headache ball fell 24 feet, striking the deck less than two feet from one of the riggers guiding the load.

After the incident, a third party inspected the crane, replaced a small three-inch pin for the hook latch, and the crane was placed back in service.

What went wrong?

- The rigger and crane operator should have noticed the auxiliary winch was no longer detecting the weight of the load.

- The engineering controls (i.e., weight indicator) provided an inaccurate representation to the crane operator of weight on the winch due to wedge socket snagging on the flange of the C-channel above the load cell.

- The crane operator and rigger failed to recognize something was wrong after repeated requests asking to lower the load and receiving the response that the line was being lowered and not seeing any movement in the load position.

- The rigger did not check the path of the auxiliary line for potential snags.

- The work team should have noticed the potential hazards of working close to the C-channel at the edge of the platform rig. The work team should have recognized the potential snag points.

- No formal risk assessment was conducted. However, a review of the task was performed.

Lessons learned

- Ensure a secondary device (e.g., weight indicator, camera) is accessible to detect any slack on the load line.

- Identify all potential wireline contact points and include them in worksite instructions, risk assessments, and toolbox talks.

- When working close to the equipment, and facility structures, identify potential contact and snag points and incorporate appropriate mitigation actions, including placing additional spotters at potential contact or snag points.

- Discuss what key controls are in place to remove yourself and your team members from the potential “line of fire” (i.e., The zone within a work area where

there is a risk of (serious) injury from machinery or equipment). - Ensure all operations and contract personnel involved in “lifting operations” attend and participate in a pre-job meeting/toolbox talk and document.

- All workers should review the Job Safety Analysis (JSA) and ensure all hazards are acknowledged and policies /procedures, guidelines,

contingencies, and communications are understood.

- All workers should review the Job Safety Analysis (JSA) and ensure all hazards are acknowledged and policies /procedures, guidelines,

- Incorporate load movement verification communications from rigger to crane operator (e.g., “down one foot,” “north one foot,” etc.) to ensure load line

movement is confirmed throughout the lift and especially blind lifts.- Do a step-by-step visualization of the move to identify snag points, mitigations, and critical communications, especially when tight clearance

cannot be avoided.

- Do a step-by-step visualization of the move to identify snag points, mitigations, and critical communications, especially when tight clearance

- Conduct proper planning before lifts, such as reviewing the drop zones and identifying safe zones during the lift(s).