The International Marine Contractors Association (IMCA) provides lessons learned from an incident in which, a main bell wire rope sample from a DSV failed to an adequate safety factor after 245 bell runs since installation.

Following this failure of the annual breaking load test the DSV reported a premature retirement of the main dive bell wire after it had been in service for approximately eighteen months from March 2021 to October 2022.

IMCA D018 Code of Practice for the Initial and Periodic Examination, Testing, and Certification of Diving Plant and Equipment guidelines are to perform visual inspection every 6 months and perform destructive tests (DT) upon installation and on an annual basis. IMCA D018 guidelines allow up to 10% reduction in minimum breaking load (MBL). Visual inspection and DT were carried out on board in line with IMCA guidelines.

The scheduled maintenance annual breaking load test completed in October 2022 achieved a breaking load of 99.9 tonnes (980 kN) 30% below MBL. In accordance with IMCA guidelines, a second test was permitted and achieved a breaking load of 108.6 tonnes (1065 kN) 24% below MBL.

Findings

A purchase order was raised by the DSV owners in December 2020 to procure the bell wire when the vessel was reactivated. The purchase was made without consultation with the company’s wire rope integrity management team, without an approved company wire rope specification, and from a non-approved supplier.

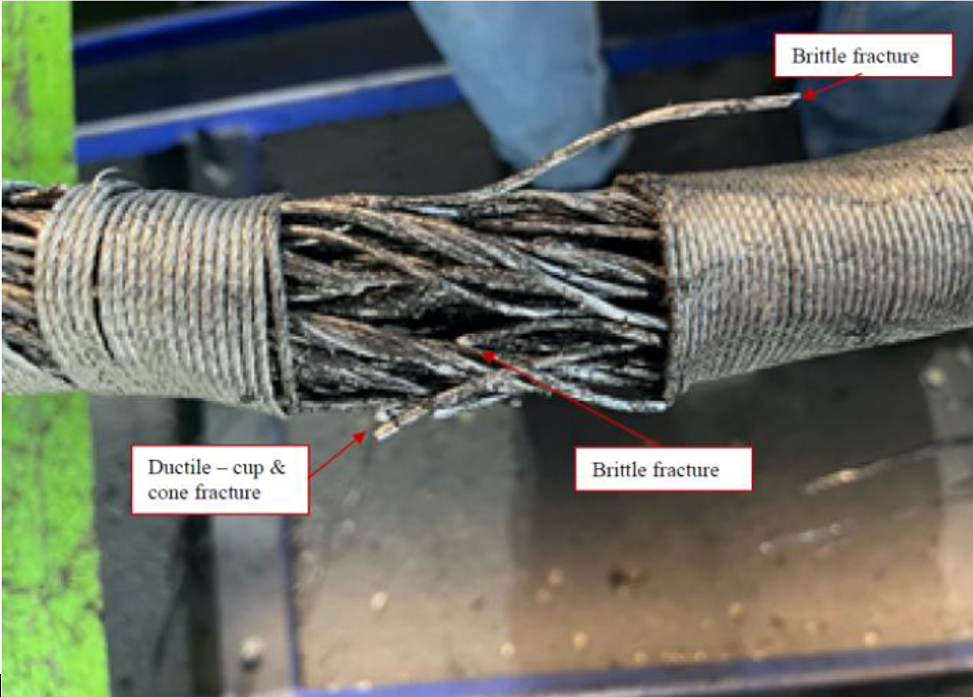

From the review of the wire fractures at the rope destruction test, it was apparent there was a number of shear fractures present indicating poor ductility. A reduced ductility was also apparent following individual wire testing as part of the investigation. Component wires of reduced ductility cause a lack of elongation in the complete wire rope, resulting in a reduced load bearing capacity.

The lack of ductility was explained by the phenomenon of strain aging, which is a change in steel microstructure leading to a change in wire properties including a reduction in ductility. The occurrence of strain aging is initially influenced by steel chemistry and manufacturing methods and is then dependent on a time and temperature relationship which can be influenced by storage conditions.

Actions to be taken

- Ensure wire rope integrity management requirements are followed at all times;

- Ensure sufficient and appropriate management and oversight of chartered third-party vessels.

- Members may wish to refer to: Crane wire parted during offshore operations