The London P&I Club issued an updated guide on the safe operation and maintenance of ship holds and hatch covers, highlighting some of the common associated causes of damage, loss and personal injury and providing recommendations on best practices and points to avoid.

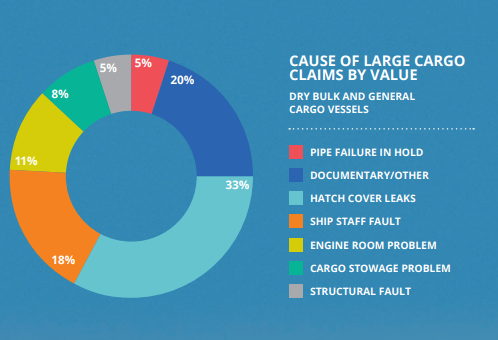

According to the Club’s data, the cause of large cargo claims by value in dry bulk and general cargo vessels accounts for 33%.

As noted, ISM Code systems should include procedures for loading, unloading, ballasting, deballasting, securing manholes, blanking ballast lines, testing bilge systems, testing alarms and even hold cleaning in preparation for the next cargo.

Safely following these procedures and recording details in relevant logbooks is very important.

Accidents often happen when hatch covers are moved.

Make sure you have the maker’s operating instructions for the hatch covers on your ship and follow them.

Do…

- Always rectify steel-to-steel faults before renewing rubber packing or rubber renewals will not be effective.

- Always keep chains and cleats correctly adjusted.

- Always attach locking pins and chains to doors and hatch covers in the open position

- Always keep coaming tops clean and double drainage channels in good order.

- Always open hatch covers and clean coaming tops and double drainage channels after loading bulk cargo through the grain or cement hatches. This must be done prior to final closing of covers for sea. always keep wheels, hinge pins and chain tension equipment well greased.

- Always keep hydraulic systems oil tight.

- Always give notice that maintenance is being performed on equipment.

- Ensure no one can start the system or equipment.

- Always prevent access hatch from being locked closed when personnel are in the hold.

- Always lock hatch covers fully open before switching off power.

- Always check wires for broken strands and fraying. Grease regularly

Don’t…

- enter a hold with suspect atmosphere;

- apply petroleum-based grease or paint to rubber packing surfaces;

- remove the rubber ball valve from drain valves;

- allow grooves to form in coaming tops in way of the side panel edges;

- use anything other than the recommended oil in the hydraulic system;

- leave cleats loose when proceeding to sea;

- attempt to open or close side-rolling covers with loads or cargo debris on top;

- screw down cleats beyond normal tension.

See also: Cargo hold cleaning: Why it matters

Explore more herebelow:

We’re in 2020. If P&I needs to highlight these issues to the vessels and their owners/operators it means the crew(s) are far off. Maybe it’s time to introduce a vetting system to the dry bulk and container fleets, with inspections every 6 months…