According to an article written for by Amanda Thurman for Wärtsilä Marine Marketing, onboard carbon capture and storage (CCS), a technology based on liquid absorption, makes it possible to reduce carbon emissions by up to 70%.

As a part of establishing a path to net zero by or around 2050, there is increasing pressure on the maritime sector to minimize its greenhouse gas (GHG) emissions. In the meantime, there has also been a growth in interest in various decarbonisation technologies and measures, like the use of carbon capture and storage on board vessels to reduce onboard operational carbon emissions.

How does a carbon capture system work?

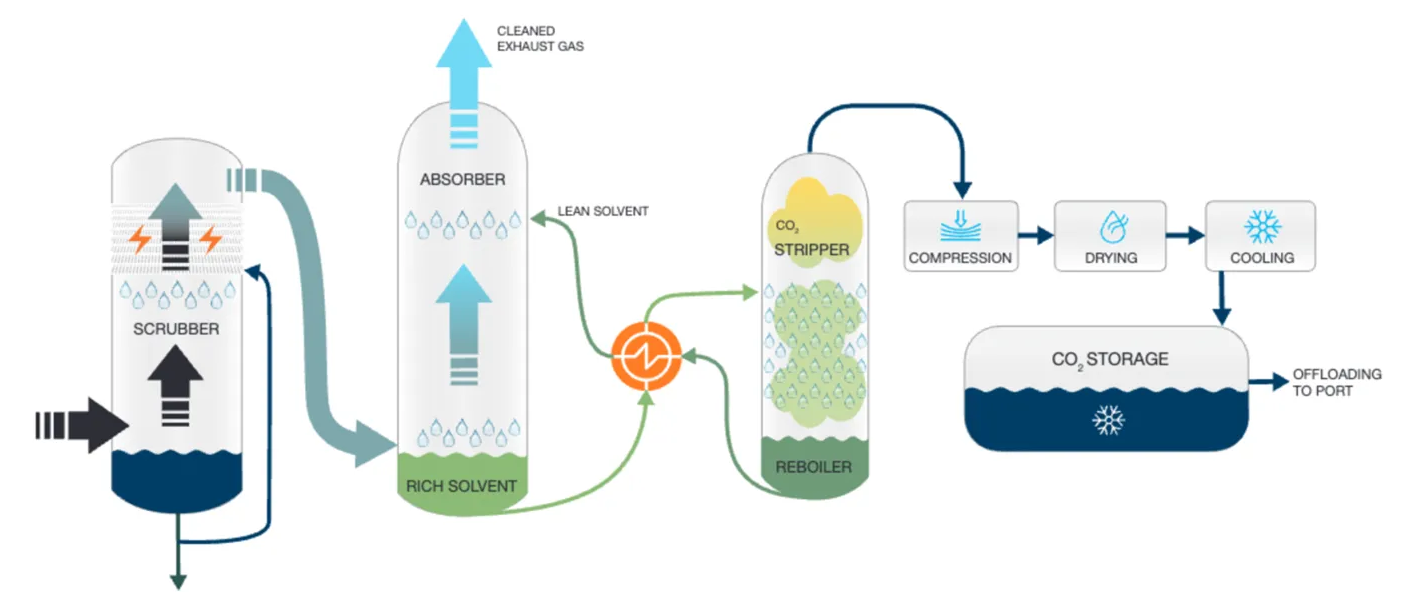

A carbon capture system has five main stages:

- pre-conditioning

- absorption

- desorption (or stripping)

- liquefaction

- storage

The first stage is the pre-conditioning

This is where the exhaust gas is cleaned and cooled down. For high-sulphur fuels this requires a scrubber to remove SOx and then a WESP to remove PM. The pre-treated exhaust gas then travels to the bottom of the absorber.

The second stage is the absorber

A liquid amine-based solvent enters the top of the absorber where the gas and solvent mix. This captures the CO2 in the solvent. The cleaned exhaust gas exits the system and the CO2-saturated solvent is pumped via a heat exchanger to the stripper.

The third stage is the stripper

The solvent is heated, releasing the CO2. The lean solvent is recirculated to the absorber and reused.

The fourth stage is liquefaction

The CO2 is compressed, dried and cooled down to liquid form for storage.

The fifth and final stage is storage

The liquid CO2 is pumped through pipes to onboard tank(s), where it is stored until it can be offloaded.