Digital Twins emerged as a technological trend in the shipping industry a while ago, but now the sector acknowledges this technology as a powerful combination of models and data, which represents a giant leap from first efforts at modelling complex systems.

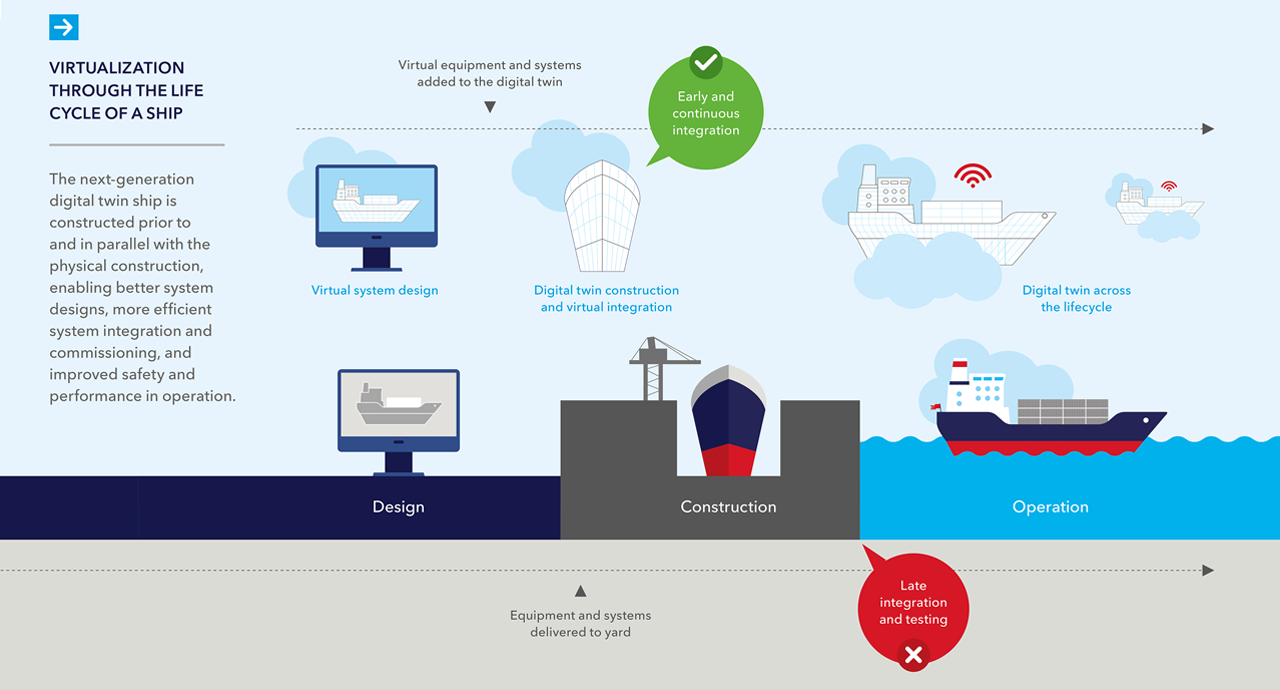

DNV GL, which recently published its Technology Outlook 2030, explains that moving towards 2030, the first step will be the digital system representations in the concept phase (3D drawings, descriptions, requirement and use-case specifications, high-level risk analyses, generative design) will be detailed and optimized throughout the design phase.

Then, the second step is that the concept phase is expanded with simulation models representing all relevant system aspects and giving operators the ability to perform complex tasks in, for example, virtual system integration.

The third step is the project management information which is then added, enabling simulation-based optimization of the installation and commissioning processes.

The next steps to be taken are the process of optimization, maintenance and modifications, as well as decision support.

In the future, the potential to store and handle huge amounts of data will enable the process of keeping the digital twin alive throughout its life-phase.

Further integration of data streams and integration of various digital sub-models (sub-twins) will, in addition, lead to the relatively easy construction (unthinkable until now) of models

… DNV GL informs.

Moreover, until now, models focus and analyse a particular aspect of an asset and then answer specific questions; For instance, a single asset, as a wind turbine, might have more than 100 separate models to answer specific questions about its condition or performance. Therefore, digital twin now brings all these models together, and along with data from the asset, develops throughout the life cycle of the asset.