Amid an increase of container ship fires in the last years, a new guide is published to serve as a route-map for the CTU Code and to assist wider understanding of good packing practices.

The ‘CTU Code – a quick guide’, results from collaboration of five partners in the Cargo Integrity Group, including Container Owners Association (COA), the Global Shippers Forum (GSF), the International Cargo Handling Co-ordination Association (ICHCA), the TT Club and the World Shipping Council (WSC).

The purpose of this guide is to facilitate the proper packing, transport and unpacking of cargo transport units (CTUs), including freight containers, in accordance with the ILO/IMO/UNECE Code of 2014.

A special online media briefing on Thursday gathered experts from the five organizations, including Captain Richard Brough – OBE of ICHCA International, Peregrine Storrs-Fox – TT Club’s Risk Management Director, James Hookham- Secretary General of Global Shippers Forum, and Lars Kjaer, senior vice president of WSC, who discussed current challenges on container packing. While CTU addresses a wide range of cargoes, the experts agreed, a Code cannot cover every cargo, and particular requirements on new cargoes could cause shippers difficulties of compliance around the world. Lithium batteries or counterfeit batteries are good examples of dangerous cargoes that cannot be covered by a single code and may need to pass some sort of reclassification.

Meanwhile, the speakers touched upon the issue of training on packing containers. As explained, the types of cargo carried in CTUs (particularly freight containers) has expanded over the years and innovations in packaging, such as the use of flexitanks, and other recent developments allow heavy, bulky items, traditionally loaded directly into ships’ holds (e.g. stone, steel, waste materials and project cargoes), to be carried instead in CTUs. The person who packs and secures cargo into a CTU, and seals it, may be the last person to look inside that unit until it is opened at its final destination.

As such, the new guide seeks to assist in planning and executing the packing of cargo so that its shipment will be satisfactory to the shipper, carrier and consignee, as well as to help in the prevention of pest contamination and damage to CTUs and their cargoes transported by road, rail, and by ship. Let’s see some points:

Packaging

The use of CTUs to contain goods has not eliminated the need for adequate interior and exterior packaging of cargo. Packaging requires careful consideration. The packaging should be sufficiently strong to accommodate stacking within a CTU and the vertical and horizontal pressures sustained during transit by road, rail or ship.

All packaging, whether it is cases, drums, crates, etc should have adequate ability to withstand all the forces of normal transport while effectively containing the cargo. The strength and required service life of both interior and exterior packaging depends on the product, the trade route, and the different modes of transport used between the point of origin and destination.

-Special packaging

- It is important that the cargo does not move within the carton, box, or other receptacle in which it is packaged. In order to immobilise the contents, it is necessary to provide adequate cushioning within the packaging and/or block and brace the contents;

- Heavy machinery and items that are not uniform in shape or dimension should be crated, boxed, or palletised to permit ease of handling and compact stowage; and

- Each carton or box should be able to withstand the weight and pressure of cargo stacked up to eight feet high.

In addition, boxes, cartons, and crates should be able to survive lateral pressures exerted by adjacent cargo of up to 70% of the vertical stacking weight. This will help to prevent crushing of contents caused by the forces encountered during transport

Packing

-General principles

When planning the packing of the CTU a number of basic rules should be applied:

- Use locking, blocking or lashing, or a combination of these methods, to prevent the cargo from sliding and tipping in any direction;

- Distribute heavy cargo over the floor area and ensure that the centre of gravity of the packed CTU is correctly located;

- Do not build up irregular layers of packages. Irregular stacks without blocking and proper securing will result in damaged cargo;

- Do not stow heavy goods on top of light goods;

- Do not stow goods with tainting odours together with sensitive merchandise; and

- Observe all handling instructions on packages such as “this side up”.

-Packing exceptional goods

- High centre of gravity cargoes (tall, small footprint and/or light support structure) are subject to tipping and falling. Such items need support from adjacent packages or cargo items in a tight stow, or sufficient space around to ensure that direct lashings can be applied;

- Heavy cargo items (with a mass greater than 0.25P9), such as machinery (which may also have a high centre of gravity) and dense cargoes (steel coils, marble and granite blocks), all require the load to be distributed onto the major structural components of the CTU; and

- Road and other wheeled transport items, drums, coils and tubes should be packed in such a way that the CTU floor/cargo deck is not compromised. Non-pneumatic wheels, coils and tubes (that may also be considered as a heavy cargo item) should be supported on beams, which should in turn be placed onto the major structural components of the CTU. Additionally, chocks of sufficient size should be placed against the curved surface and affixed to the supporting beams. Chocks should not be nailed to the CTU deck.

-Packing Dangerous Goods

Chapter 10 of the Code provides packers with additional advice on the packing of Dangerous Goods:

- Check that all packages are properly marked and labelled;

- Pack Dangerous Goods near to the doors if possible;

- Affix required placards on the exterior of the CTU; and

- Do not pack damaged packages.

-Commodity specific packing and securing instructions

The variety of cargo types and package designs means that it is impossible to provide specific detailed guidance in this document. Commodity/packaging specific guidance may be available; seek information from the CTU operator.

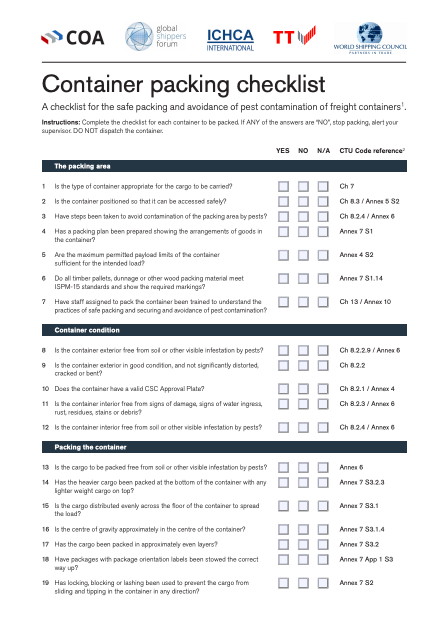

Container Packing Checklist

The guide includes a checklist for intermodal freight containers for safe packing and avoidance of pest contamination based on CTU Code. This checklist sequences the main check-points from a container packer’s perspective, supporting sound decision-making. Successful completion facilitates safe and secure dispatch of a container.

Click to see the whole checklist:

Find out more guidelines herebelow: