Alfa Laval PureSOx systems will soon be installed by Hanjin Heavy Industries and Construction aboard two LPG carriers for Belgian owner/operator EXMAR. Because these vessels are newbuilds, the installations place Alfa Laval’s planning, documentation and delivery capabilities in the spotlight.

Hanjin Heavy Industries and Construction recently was contracted by Belgian energy logistics company EXMAR for newbuild LPG carriers that will join EXMAR’s existing LPG fleet of around 30 vessels. The new LPG carriers, each with a capacity of 38,000 m3, will be built at Hanjin’s Subic Shipyard in the Philippines and delivered to EXMAR in Q1 and Q2 of 2016.

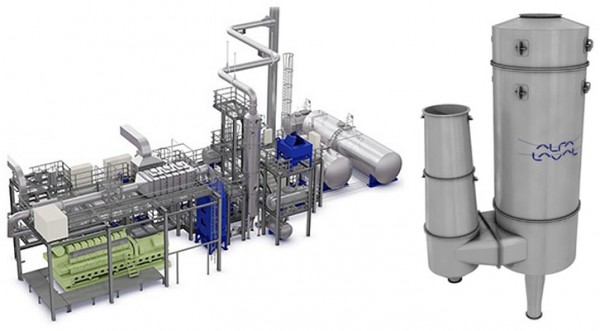

Two of these vessels will be equipped with Alfa Laval PureSOx scrubber systems for exhaust gas cleaning, which will be delivered to the Subic Shipyard in December 2014 and March 2015. The systems will be configured as hybrids, able to operate in an open loop with seawater or in a closed loop with circulation water. Each multiple-inlet system will serve a two-stroke Doosan MDT 6S59ME-B 9.3 main engine and three Doosan MAN 8L23/30H Mk2 auxiliary engines.

As newbuilds, these installations place especially high focus on Alfa Laval’s order execution capabilities.

“The choice of exhaust gas cleaning from Alfa Laval is based not only on the merits of the PureSOx system itself, but also on Alfa Laval’s merits as a scrubber supplier,” says Lee Dong-hoon from Hanjin’s senior management.

With 2015 rapidly approaching, much focus has been placed on the retrofit of existing vessels to comply with SOx limits in Emission Control Areas (ECAs). Yet the task of incorporating a scrubber into a newbuild can be an even more demanding procedure for both customer and supplier. Substantial differences exist in the process, beginning with the quotation stage.

“The purchase order for a newbuild – unlike that of a retrofit – includes yard-specific demands that must be taken into account,” says René Diks, Manager Marketing & Sales, Exhaust Gas Cleaning at Alfa Laval. “As the scrubber supplier, we must be well prepared to clarify and motivate any technical deviations between our system and the shipyard’s own thinking. This is the basis on which the shipyard makes an informed choice, before the terms and conditions of the contract are even handled.”

To secure the efficiency of both approval and delivery, Alfa Laval has established a range of best practices for PureSOx. These extend from having a dedicated project manager who ensures reliable project execution to providing a range of specialized documentation.

“In general,” says Diks, “Alfa Laval’s scale and experience in exhaust gas cleaning allow a level of project-specific optimization that would be difficult for a smaller supplier to match.”

Besides the initial technical specification and final project-specific guidelines, Alfa Laval provides a detailed design guide and comprehensive installation manual that support the interaction of the shipyard, end customer and any engineering company involved. Combined with Alfa Laval’s strong global logistics, dedicated project management and the prefabrication of PureSOx components and modules, this ensures a well-planned, precisely timed and smoothly executed installation at the shipyard.

“Alfa Laval has made things easier in our work with EXMAR so far, and we anticipate that will continue as the EXMAR projects progress,” says Lee. “We expect a lot from Alfa Laval as an experienced marine supplier, and when it comes to the professional level of support regarding PureSOx and exhaust gas cleaning, the company delivers. We are very satisfied at present.”

Source and Image Credit: Alfa Laval

In the onset, I was outspoken with you propecia before and after has changed my existence. It has become much more fun, and now I have to run. Just as it is improbable to sit.