Liberian Registry invests in new technology

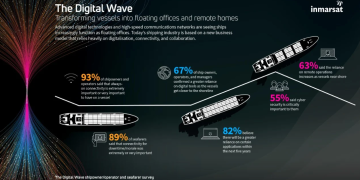

Strengthening position as safest major flag The Liberian Registry has developed a unique satellite-based Compliance Assistance Programme (CAP) which has helped ensure regulatory compliance and prevent detentions in some of the world's most active Port State Control (PSC) areas. In the process, it has contributed to Liberia being named as the best-performing major ship registry worldwide over the last three years, a period during which it has featured on all PSC White Lists and has been included in the prestigious US Qualship 21 programme. Moreover, during this same period, the Paris Memorandum of Understanding (MoU) statistics confirm that Liberia had the best detention rate amongst the largest major flag states.The development further strengthens the leading role which Liberia has established over a number of years as the world's most technologically innovative flag state. The CAP tracks ships when they enter selected jurisdictions and allows the registry's risk analysis team to perform detailed reviews of vessels, their history, and the ports at which they are calling. As a result, Liberian vessels have experienced a decrease in detentions in heavily trafficked PSC regions such as China.The CAP supplements the existing electronic services already provided by Liberia and is part of a program ...

Read more