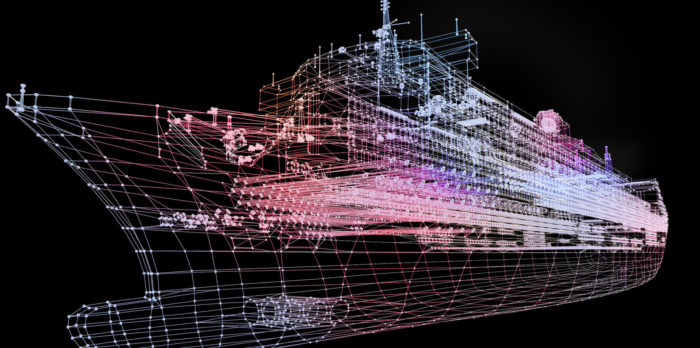

A bulk cargo carrier was recently the test site for various remote inspection techniques (RITs) that demonstrated how robotics solutions can esnure quicker, safer and more efficient ship inspections.

Different types of RITs were recently tested on a double-skin supramax bulk cargo carrier. The testing was carried out by Belgian certification company Bureau Veritas that established proof of concept and confirmed the operational purpose of the remote tools.

The RITs included an aerial drone, magnetic crawlers and a miniature remotely operated vehicle (ROV).

The inspection took place during the bulk cargo carrier’s recent visit to the Neorion shipyard on the island of Syros, Greece, for work on the stern requiring a specific ballast condition. The miniature ROV was used to perform the underwater inspections of flooded tanks, eliminating the need for deballasting.

Additionally, the holds and structure were examined by the aerial drone and magnetic crawlers equipped with ultrasonic thickness measurement (UTM) sensors.

By moving across both vertical and inverted planes, the drones and crawlers also provided the steadiness needed for close-up pictures and UTM readings.

Oceanbulk Maritime’s Milena Pappas commented on the RIT testing:

During the tests on site, it was evident that robotic services could be a very useful and efficient tool, especially in difficult areas (upper parts of cargo holds) and during adverse conditions (full ballast tanks). By utilizing drones and ROVs, all close up inspections and UTM could be completed in a much safer, efficient and quicker way

This effort furthers the BugWright2 (Autonomous Robotic Inspection and Maintenance on Ship Hulls and Storage Tanks) project’s goal to change the European landscape of robotics for infrastructure inspection and maintenance.