The Bahamas Maritime Authority (BMA) has issued a safety alert to share lessons to be learned from the death of a subcontractor, working at height on a pipe laying vessel.

The incident

A Bahamas flagged pipe laying vessel was mobilising for a project at anchor. Work was scheduled to be conducted by vessel crew and various subcontractors, with each team independently completing their permits to work, following the vessel’s safety management system’s requirements.

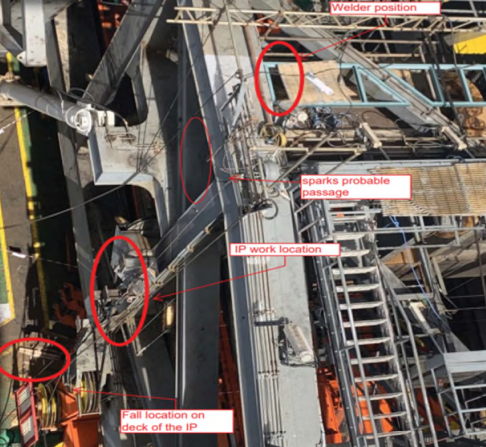

Permit controlled work on the J-lay tower included work aloft by a rope access team tasked with preparing and painting new steel work. This was to be completed with hot work ongoing at a higher level, where a new platform structure was being welded in place.

The welders had already started work when the rope access technician and assistant arrived at their work area. The assistant raised concerns about visible sparks, but the rope access technician assured him that the risk was negligible, and proceeded to climb to the work area with an open container of paint thinner attached to his safety line.

The assistant went to the paint locker, leaving the rope access technician at the work area. Meanwhile, the welder’s assistant noticed the rope access technician, but did not mention anything to the welder.

Shortly afterwards, sparks from the hot work ignited the paint thinner. The rope access technician pushed the paint thinner container away but the ignited material splashed onto the safety harness, causing it to melt and fail. The rope access technician fell approximately five meters to the deck and died from his injuries.

Safety Factors

- Simultaneous Operations (SIMOPS) are described by the International Maritime Contractors Association (IMCA) as the potential clash of activities which could bring about an undesired event or set of circumstances. SIMOPS often involve multiple companies (owners, contractors, subcontractors) and a large multi-disciplined workforce carrying out various activities concurrently.

- The full marine safety investigation report can be accessed here but attention is drawn to the following factors that contributed to the casualty:

- lack of full team representation and involvement in pre-planning meetings

- safety management system requirements were implemented, but in isolation:

- rendering them ineffective by other simultaneous operations

- inadequate high-level supervision and control for multiple activities

- the vessel’s “stop work” policy was ineffective

Lessons learned

- While conducting simultaneous operations, effective supervision means maintaining oversight of the entire operation to enable identification of areas which overlap and the associated potential risks.

- During simultaneous operations, job safety analyses (JSA), permits to work (PtW) and risk assessments lose their effectiveness if each team completes their own in isolation. It is important to think of ship and crew safety holistically, not as isolated departments.

- Work planning meetings should include (at minimum) a supervisor or representative of each independent team to ensure all teams have a unified understanding of ongoing operations and how it relates to their work. This contributes to an overarching understanding of risk, rather than just a team specific focus.

- Stop work authority is a safety policy that authorizes employees to put a stop to unsafe work, even when they normally don’t have that level of authority. It is only effective when considered more than a written policy and actually utilized. All shipboard personnel and subcontractors alike, should be aware of this, while managers should emphasize there are no repercussions to crew who choose to exercise their stop work authority. Operations should not be dependent upon the intervention of senior staff or supervisors to determine that work is safe to carry on, this practice is detrimental to onboard safety culture. Stop work authority can be used to reassess risks and reset a scenario, potentially saving a life.