BSEE was informed about several recent events involving the improper use or disposal of chemicals, and provides lessons learned.

The incidents

Incident 1: During the disposal of expired paint products, a worker mixed epoxy resin and solidifier in a container. In a second container, Carboline epoxy paint A & B components were mixed. Finally, the two containers were mixed into a five-gallon bucket and placed in a paint locker. Five minutes later, the worker noticed smoke coming from the locker. The worker placed the bucket into a larger container filled with water and left. Twenty minutes later, the worker’s supervisor noticed white smoke coming from the container and called the control room. The platform was shut down and personnel mustered. The worker added more water to the container enroute to his muster station, but the smoking did not stop until later when the mixture was covered with fire retardant powder.

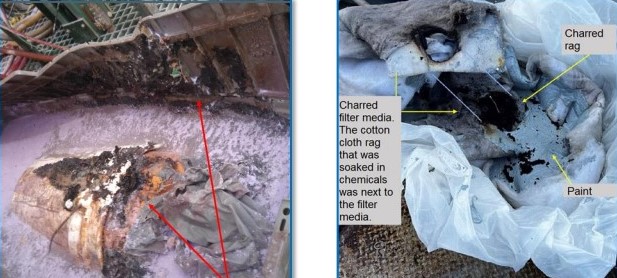

Incident 2: An operator noticed a cotton cloth rag smoldering inside a wheelbarrow. The wheelbarrow also contained filtration media and used paint that was curing before disposal. Water was used to put out the fire. The investigation determined that the cloth likely contained flammable Carboline thinner, which ignited as the cloth dried in direct sunlight.

Incident 3: An employee attempted to clear a clogged drain in the living quarters with Liquid Fire drain cleaner (active ingredient: sulfuric acid). The employee then added additional drain cleaner on the mornings of the next two days without success. At 19:30 on the third day, the employee added chlorine bleach to attempt to unclog the drain. The bleach and drain cleaner reacted causing a small greenish yellow gas cloud to form. The employee inhaled a small amount of the gas and experienced a sudden shortness of breath. The employee was medivacked to a hospital for chest x-rays, supplemental oxygen, and breathing treatment and was later released.

Lessons learned

BSEE recommends that operators consider:

- Mixing a smaller volume of chemicals first to verify that the mixture will not be hazardous and not leaving the mixture unattended until it has cooled. When epoxy base is mixed with solidifier, the reaction may be exothermic (i.e., produce heat).

- Avoiding leaving cloths, rags, mops, or clothing that have been saturated with flammable liquids in hot areas or direct sunlight. Laundering these items without first removing the flammable liquids can cause fires.

- Not mixing cleaning products. Follow the instructions provided by the manufacturer and do not use them for purposes other than their designated use.

- Reading the Safety Data Sheets (SDS) and developing procedures for handling chemicals that account for their specific hazards. Keep SDS on file for all chemicals kept in inventory or used routinely at your facility. SDS include information about hazardous chemical properties, personal protective equipment (PPE) requirements, and procedures for first aid, handling, cleanup, firefighting, storage, and disposal.

- Verifying that firefighting and spill response equipment is nearby and ready for use before starting a job. Some firefighting formulations may not be effective against certain chemicals, and water may worsen some types of fires or chemical reactions.

- Wearing proper PPE when handling chemicals. Face shields, special chemical handling gloves, and aprons are common PPE for chemical handling. Latex gloves may be sufficient for some chemicals; others may require PVC or nitrile gloves. Refer to the SDS for PPE information.

- Using turn-key service contracts that include disposal of unused chemicals and paints by experienced personnel.

- Establishing an inventory management system that covers the full life cycle of chemicals kept in inventory at your facilities. Improperly stored or expired chemicals may create additional hazards or complicate disposal.