For centuries, the shipping administration has been collecting huge amounts of manual scripts and reports in and continuous effort to maintain the OPEX and the CAPEX under control. Only the last few decades Technology (Telex, Fax, emails, smart control systems) have managed to bring the ships closer to Onshore Operations and secure the existence of at least one report per day, notes Mr. Christos Giordamlis, CEO, Prisma Electronics.

Only recently data is turning slowly and gradually the Shipping Industry to a “Data-centric Operations”. The ability to utilize data, to obtain knowledge, predictions and insights gives today the tools for continuous process improvements and a path to optimal performance throughout the lifetime of assets. Today, by applying advanced analytics to collected data (new and historical fleet automated, with a sampling rate less than a minute data) and by using big data visualization techniques to present the insights, ship owners are able to monitor their vessel’s status and condition in a different manner. Thus to make data-driven decisions that support more efficient operations is approaching fast and will change existing principles.

Despite the significant number of offshore monitoring related projects conducted all over the world, they are almost entirely limited to single asset management, or fleet benchmarking on a statistical basis. Advancements in Machine-to-Machine communication and Cloud Computing, that enhances Industrial Internet of Things technology, has been treated in shipping with data mining tools delivering off-line processing of data.

Real time Data exchange between Connected Assets, Connected Vessels, long-distance remote located offshore structures (e.g. between vessel and weather forecasts, hurricane prediction stations, UAV/ROV monitoring systems, ocean ecological environment monitoring) is still not available Unmanned and Autonomous Vessels or communication between vessels in low-coverage areas and on-shore is a key challenge for the next generation of smart shipping: the Internet of Ships.

Although a lot could be written about the enormous amount of possibilities and applications such a network could enable, we only mention the self-describing key drivers leading the way towards that direction:

- Safety and wellness of crew

- Environmental Issues & Regulation

- Security of assets

- Dynamically adjusted Efficiency of operations

When it comes to multi structure network architectures, there is need to focus on several issues concerning the transmission of information, mainly due to

- Adverse conditions within specific offshore environments,

- Lack of Interoperability within the main Vendors

- Faults on data produced, Noise and diverse EMC environment

- Long distances between the nodes,

- Dependence of the system on the main power supply network

- Latency/bandwidth limitation on satellite communication network,

- Cybersecurity issues,

- Variety of data exchange formats and systems

In addition emphasis has to be given in fulfillment of the requirements highlighted in the literature:

- Need for smart monitoring instruments with less power requirement, higher accuracy, ability for synchronization, and applicable in a variety of sensor types and ideally on fiber-optic sensors.

- Need for efficient wireless communication network that allows multi-measurement acquisition and real time data exchange between different offshore structures and between offshore structures and third parties (e.g., port authorities).

The promising features of the forthcoming 5th generation (5G) mobile networks (e.g., low energy consumption, reduced latency, increased efficiency) assisting the aim of integrating multiple offshore structures into a wider ecosystem for the exchange of large dimensional structured information leading to an efficient and comprehensive operation of the offshore assets through Information Intelligence.

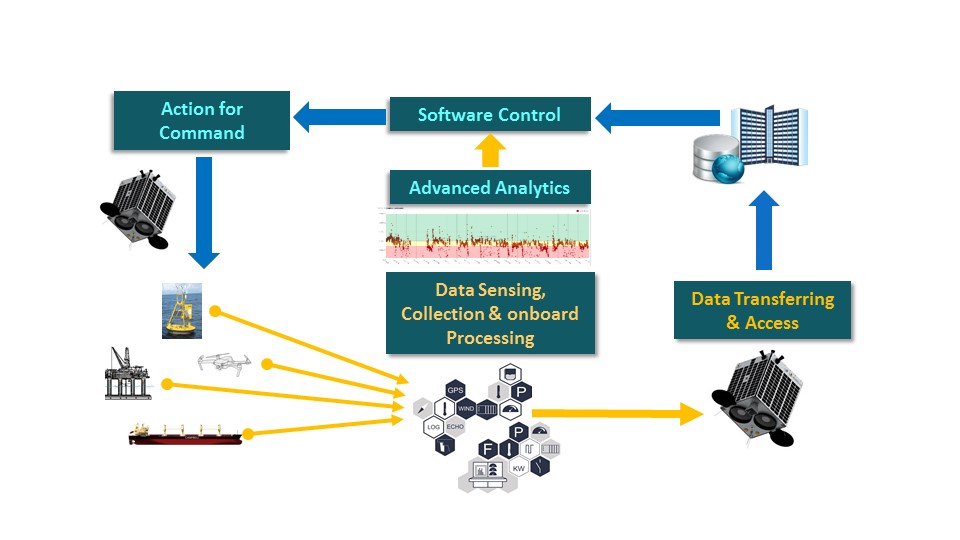

The development of 5G-based Low Earth Orbit (LEO) satellites will further enhance the integration of satellite and terrestrial networks in 5G, enabling thus even larger or distant located eco-systems (e.g., deep water oil platforms). Figure below schematically presents such an integrated architecture.

State-of-the-art technology trends in various sectors including M2M, intelligent processing, machine learning, data agents, actuators, cyber-safe datasets, telco etc., should be part of new generation platforms to secure data science in a level that allows the Shipping Industry to enter the I-IOT – 5G area dynamically and support effectively decisions, safety, efficiency and interoperability.

The key technological challenge towards the way from Smart Shipping to Internet of Ships is the development of a unique platform architecture that allows a reliable, uninterrupted reception and management of data from a wide range of sensors within a wide range of offshore structures. We are currently working towards that direction focusing on:

- Single Vendor approach in producing reliable data close to the signal source.

- Integration of sensing and energy harvesting units in shelf -powered energy autonomous optoelectronic sensing nodes with wireless connectivity in wireless sensor networks.

- Implementation of technologies like Lattice-Valued Reasoning for real time integration of human and artificial intelligence.

- Historical Data, Pattern Recognition, Machine Learning and Deep Learning approaches to digest Big Data into a decision support system

- Enhancement of Cloud computing and storage with Fog computing for shipping, allowing thus real time management of information and enhancing the crew operational and maintenance procedures through Augmented Reality

- Combination of low power Mesh networking utilizing also satellite and 5G to allow communication at long distances in an efficient, low energy and less costly way.

- Smart Actuators that boosts efficiency and performance control on connected assets.

The goal for the shipping industry is to the next step would be to define the important details in order the designed platform architecture to offer a reliable and usable monitoring system even in harsh and non-accessible until now environments. The journey has just started, Internet of Ships is rising and only those with sufficient connected and related Big Data will prevail to this demanding market.

By Giordamlis Christos, CEO, Prisma Electronics

The views presented hereabove are only those of the author and not necessarily those of SAFETY4SEA and are for information sharing and discussion purposes only.

Giordamlis Christos is the CEO of Prisma Electronics. Prisma Electronics SA was established in Alexandroupolis, in 1991, as a computer reseller. In the following years the company became the specialised ICT systems (guidance systems, ICT system Integrator, Networks (FTTH, FTTP, WLAN), collect data from sensors). Prisma’s LAROS is a dedicated, vendor agnostic, platform aiming at the continuous collection of important information from the ship’s inputs, the transmission of the data through a wireless network, centralization and homogenization of information in central computing, and analysis of measurements to support the decision-making mechanism of shipping companies. The system is using the vessel’s communication systems (satellite) to transmit all collected & synchronized data to the Headquarters, by a very efficient manner in terms of cost, speed, and security. Transferred data are further processed using LAROS Data Analysis System, an advanced software for data effective visualization and comprehensive analysis of performance.

Giordamlis Christos is the CEO of Prisma Electronics. Prisma Electronics SA was established in Alexandroupolis, in 1991, as a computer reseller. In the following years the company became the specialised ICT systems (guidance systems, ICT system Integrator, Networks (FTTH, FTTP, WLAN), collect data from sensors). Prisma’s LAROS is a dedicated, vendor agnostic, platform aiming at the continuous collection of important information from the ship’s inputs, the transmission of the data through a wireless network, centralization and homogenization of information in central computing, and analysis of measurements to support the decision-making mechanism of shipping companies. The system is using the vessel’s communication systems (satellite) to transmit all collected & synchronized data to the Headquarters, by a very efficient manner in terms of cost, speed, and security. Transferred data are further processed using LAROS Data Analysis System, an advanced software for data effective visualization and comprehensive analysis of performance.