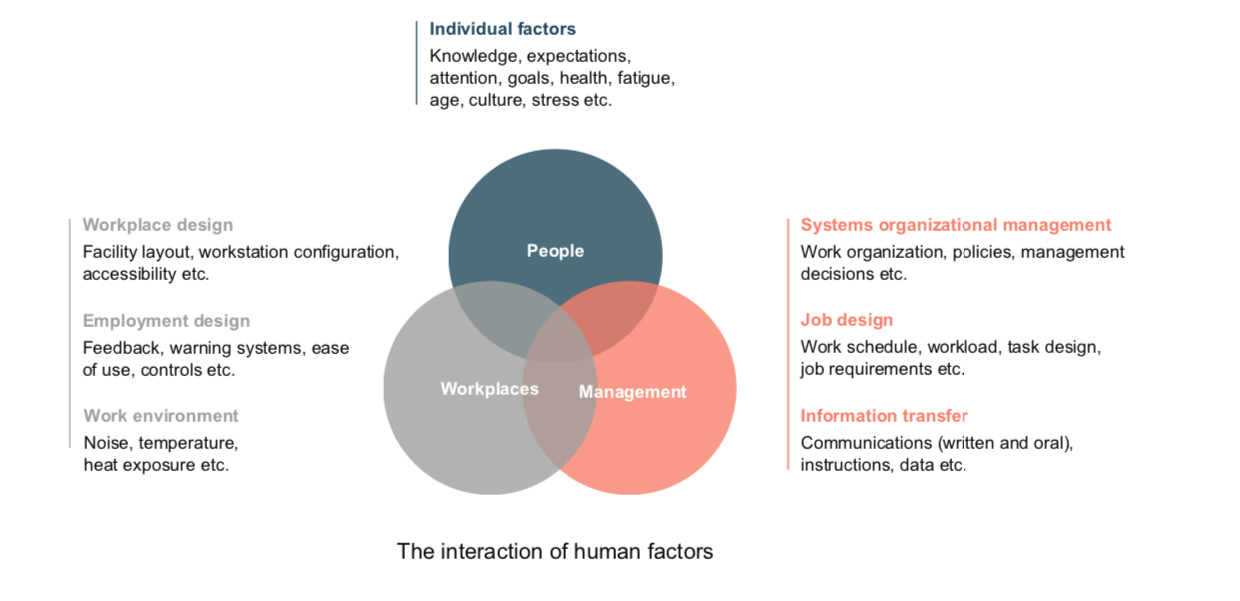

What are Human Factors? Human Factors are the physical, psychological, and social characteristics that affect human interaction with equipment, systems, processes, other individuals, and work team(s).

It is the environmental, organizational and job factors, and human and individual characteristics, which influence behavior at work in a way which can affect health and safety.

Why Human Factors?

According to the European Maritime Safety Agency (EMSA) 2019 report on “Annual overview of marine casualties and incidents 2019”, 2 out of 3 of all incidents (between 2011 to 2018) were contributed by human factors. The top factors include (1) 10.5% -lack of safety awareness, (2) 10.2% -inadequate work methods, and (3) 8.5% -poor planning and coordination.

The Maritime & Coastguard Agency Marine Guidance note (MGN 520 M) summarises a wide range of contributory factors that result in maritime accidents, incidents and errors. A consistently occurring factor is the human factor. The top three are Situational Awareness -do you know what is really happening?(22.5%), Alerting -do you really speak up when you should? (15.3%),and Communication -do you really understand each other? (13.4%)

The Maritime & Coastguard Agency Marine Guidance note (MGN 520 M) summarises a wide range of contributory factors that result in maritime accidents, incidents and errors. A consistently occurring factor is the human factor. The top three are Situational Awareness -do you know what is really happening?(22.5%), Alerting -do you really speak up when you should? (15.3%),and Communication -do you really understand each other? (13.4%)

The Oil Companies International Marine Forum (OCIMF) also issued a briefing paper in October 2020 on “The OCIMF Human Factors Approach -A framework to materially reduce marine risk”. It aims to improve safety and environmental protection in the maritime industry by considering human factors when providing guidance and recommendation. OCIMF’s goal for coming up with this paper is to reduce risk to crew, ships, and terminals by systemically addressing the systems and latent conditions that influence errors, actions, and decisions.

OCIMF believes that human factors are to be adopted as i) most widely recognized; ii) addresses all individual, system, and organizational issues; iii) best supported by institutions that cater to human-centered disciplines and iv) is consistent and goes beyond International Maritime Organization (IMO)requirements associated with the human element.

How to apply Human Factors into the workplace?

Human Factors: A System And Technology Approach

- Understand the strengths and limitations of humans.

- Study the interaction of people with equipment, technology, systems, workplace, and environment etc.

- Evaluate and design better technology, systems, workplace, and environment.

OCIMF came up with a framework to understand how human factors affect risk management and how to apply best practices. The five focus areas of human factors that form the pillars of the framework are:

Framework

- Leading and shaping the culture you want

- Well-executed tasks and procedures

- Well-designed equipment and controls

- Skills to respond to emerging situations

- Learning before and after things go wrong

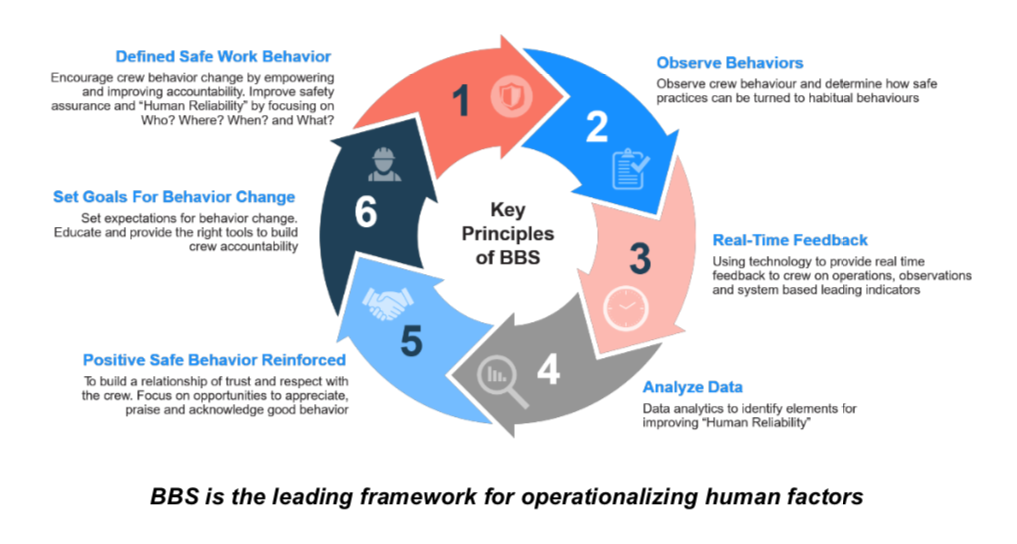

The Behavioral Based Safety program is an established method in implementing human factors in the workplace.

What is Behavioral Based Safety (BBS)?

It is a methodology in implementing safety programs which emphasises on the risk-enablers that are created due to human factors. It is intended to address the effects of a given procedure, work method, selected control measures, trainings, machinery/equipment design, environmental conditions (human factors) etc. on how it influences a person to perform the task safely.

The methodology relies on allowing persons to work as is and a third person observing them performing the task end-to-end, intervening only if there is imminent danger. At the completion of the task or at a suitable stop point, the observer* will have a positive non-judgemental discussion with the worker(s) on the observations made. The two-way discussion will revolve around why certain practices are being done, regardless of if it is good or detrimental to the worker’s safety.

The discussion will then help to validate and raise issues regarding:

- effectiveness of current practices.

- hazards or unsafe conditions which the task performer faces which are unconsidered by the supervisor/office personnel.

- the safety culture and perception on the need for safety during work.

During the discussion, good practices will be commended and positively enforced and if a new control measure, work method, or procedural suggestion is “found”, it will be considered in future safety review sessions. Negative observations discussion will revolve around why it was performed as such, with the intention to determine if there are gaps in the current safety programs. Suggestions from both parties on how to improve the situation will follow, with both parties agreeing on a way forward to perform the task in a safer manner. This will also provide empowerment for change especially to the end user (i.e. worker/crew) of safety programs.

The discussion does not become a channel to reprimand or used to penalize the observed worker/crew. If this occurs, future BBS Observation (BBSO) will be skewed as the trust between the observer and task performer is affectively negative.

#Tasks observed also includes, for example the discussion of the permit applicant (Responsible Authority) and the permit approver (Master), the inspection of a workplace as per the checklist etc. and not just the work activity per se.

*The term observer here is encompassing in this context, and does not necessarily require an actual person, for instance if there is a system which allows the data to be meaningfully collected, that event is “observed”.

The information gathered in the observation phase will be collated and analyzed to identify if there are any weak signals to indicate an underlying issue. Together with feedback of the crew, a fit for purpose solution can then be implemented to prevent an incident. Positive behaviors and practices are also picked up and these measures will be implemented where possible, enabling the crew to be empowered in ensuring that the work place is safe.

The information gathered in the observation phase will be collated and analyzed to identify if there are any weak signals to indicate an underlying issue. Together with feedback of the crew, a fit for purpose solution can then be implemented to prevent an incident. Positive behaviors and practices are also picked up and these measures will be implemented where possible, enabling the crew to be empowered in ensuring that the work place is safe.

The cycles of a BBSO program will allow continuous engagement of the leaders with the front liners, creating a safer workplace where the human factors are being taken into consideration.

Current shortcomings in implementing BBSO programs to drive a safer work environment via Human Factors

- Ratio of observers vs observable activities

Dedicated safety personnel to a workforce population at a given work place varies between 1:200 for office-like or manufacturing lines to about 1:50 for high-risk sites such as the oil and gas production sector. For an organization embarking on a safety culture change through the utilization of BBSO programs, the ratios limit the number of observable activity achievable at any given amount of time.

This issue is compounded for the maritime industry, where the workforce is disparate across the globe. Data collected will at best be a sampling of the entire population and may not reflect the actual conditions for each seafarer.

- Quality of information gathered from the observations

Persons assigned as safety personnel at a workplace can vary in terms of their knowledge, skill, and experience to carry out their duty. This can result in a myriad of quality in observations that is being made across work activities in the organization.

Poor observation quality, primarily where hazards or non-compliance are not identified properly, can lead to control measures and programs that does not tackle the real issues that needs addressing on the ground. Perception of the organization’s safety management will be affected as the workforce will be led to believe that the leaders do not know what is happening during their work.

- Quantity of information gathered from the observations

For a given work activity, typically about 4 to 5 observations can be made identifying the (potential) hazards that needs to be addressed immediately and/or requiring higher level of interventions to improve the work conditions. In the traditional manner where these observations are being made using pen and paper, the information needs to be transferred over to a digital format for further processing of the data. Accuracy, information loss and time loss are some of the issues that can occur during this transfer process.

- The need to have an analytical eye to detect a positive/negative trend

Data collected from ground observation will need to be analyzed by a data specialist to identify leading indicators or latent issues that can affect the safe work conditions or behaviors at the workplace. Ideally the Data Analyst should be safety trained to meaningfully identify trends that relate to the worksite safety performance.

- The need to match good practices on the ground with the problems that are observed

Observations seen on the ground also include good practices or control measures that the work groups have formulated to ensure that the task can be performed safely. These good observations recorded will also need to be run through the issues that were identified previously, thus a matching of these good practices to problems that is identified at another worksite may be affected by data loss and/or accuracy of matching the practices to the correct hazards. This can result in a mismatch, or that a good practice will end up being only performed in an isolated location/work group.

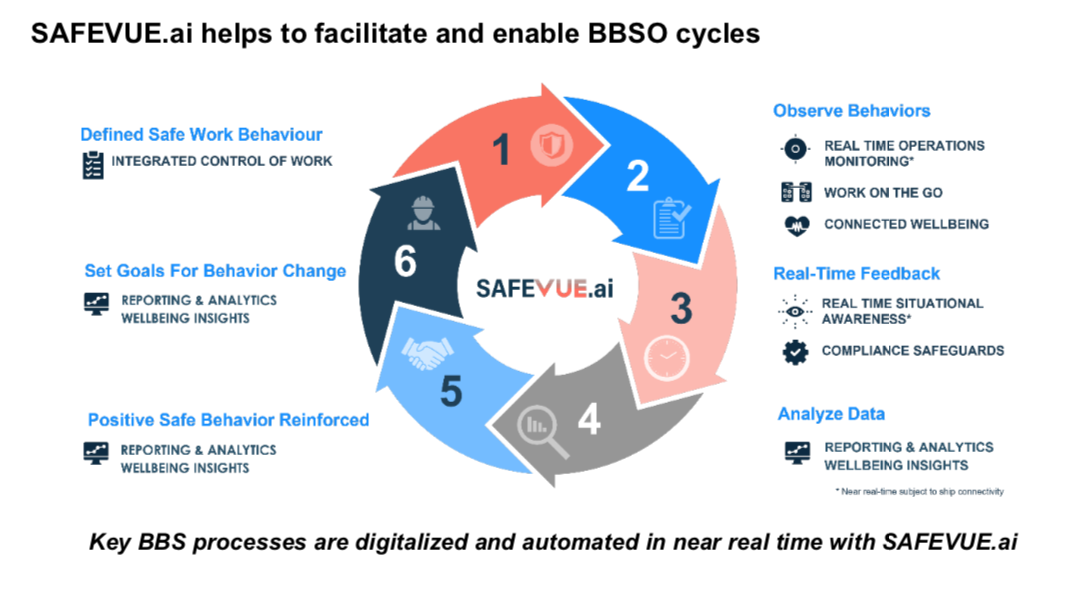

1. Safe work practices are implemented and safety culture is promoted within the organisation (Defined Safe Work Behavior)

1. Safe work practices are implemented and safety culture is promoted within the organisation (Defined Safe Work Behavior)

SAFEVUE.ai Control Of Work streamlines step by step smart safety workflows, to improve compliance assurance, Control Of Work planning and execution. The solution offers integrated permits to work, which includes Detailed Risk Assessments, safety checklists, gas readings, Electrical Isolation Certificate(EIC)with remote shore approvals and enclosed space monitoring.

This ensures compliance safeguards as when the crew is preparing a permit at key stages, he needs to enter location and time stamp verification such as EIC, sign offs. The roles and approval controls are also customized to different levels of authority for specific workflows, using unique crew identification.

The whole process ensures the right person is at the right place at the right time conducting the right task. There is proactive crew behavior change as the crew is empowered to take ownership and accountability for the tasks performed.

2. Real Time Operations Monitoring (Observe Behaviors)

Live dashboard in SAFEVUE.ai solution enables near real time vessel wide visibility of front-line operations through its display of live crew member location, identity, and their active tasks. This ensures more efficient workflow management with up to date Permits To Work time validity.

From real time operations monitoring, it also provides a holistic overview of cumulative risk and high-risk work activities. Master or Responsible Authority will be alerted with crew assist notifications if crew happen to encounter difficulties in performing their tasks or are feeling unwell. This results in improved response, better crew communication and turnaround time on critical tasks.

On the other hand, crew can perform on-site safety checks and permit documentation, and signoffs in offline mode with mobile approvals using their intrinsically safe devices. This enhances compliance, improves productivity and turnaround times by working anywhere on the vessel.

3. Situational awareness of conditions on the ground, from the crew level up to the shore personnel (Real Time Feedback)

Most of the fundamental pillars of BBS can be managed through the solution. With the availability of wearables for every crew member, crucial information with regards to the working conditions, hazard exposure periods, and other work-related hazards faced by the crew can be detected.

Immediate remediation actions can be performed by the Master and/or any persons with authority at any point of time whenever he or she reviews the current situation or trends emerging. The information therein be made accessible for persons in the organization across the hierarchy. This includes empowering the crew themselves in performing their own preventive actions when they are being alerted of a dangerous situation.

It also reinforces positive behavior, for example, when the crew is exposed to heat stress environment, and alerts to notify them to hydrate and take short breaks as needed. When real time interventions like geofence alerts, which the crew receive on their wearables while approaching near hazardous zones, they immediately avoid that area. Crew often get engrossed with their task so this could also be a good tool to break the monotonous routine and carry out Take-Five.

4. Ensured quality of data for information that is gathered by SAFEVUE.ai (Analyze Data)

With the near instantaneous information transfer and the conditions the crew members face on the vessel, data for formulating safety programs can be ensured that they are of good quality. This can help the organization in having confidence that their targeted safety programs are based on sound observational data sets.

In addition, active sensors on the wearable enables capture of crew insights and leading indicators that bring about better efficacy of corporate wellness programs and HSSE plans. This also empowers crew with near real time data to manage immediate risks when the wearable monitors crew safety and well being through important health signals, notifications, and recommendations. Crew can also take ownership by recording their working hours via their wearables. Responsible Authority may step in to proactively manage crew workload if there are leading indicators of potential work hours violations.

5&6. Ready-made analytics and possible solutions for organizational usage, backed by an experienced team of Safety Personnel and AI (Positive Safe Behavior Reinforced/Set Goals For Behavior Change)

From the data gathered from observations on the ground, SAFEVUE.ai will be able to generate actionable insights into the possible underlying root causes to issues that are being identified. These insights can also be used for standardization and sharing of best practices, and leading indicators for continuous improvements such as benchmarking high-risk activities fleetwide, time spent preparing and executing permits. Organizations can then pinpointing a more efficient and faster manner to tackle issues that can impact the safety performance and try to aim for non-compliance towards zero incidents.

In summary, SAFEVUE.ai solution empowers the organization to take the necessary steps in improving the safety conditions and practices across all levels via metrics that are being measured and accessible in real time. Overtime, the crew will be empowered, trained, and inclined to be safe as this becomes a habit.

Sources:

1) “Work At Heights – Managing the Human Factors” presentation by Assoc. Professor Chui Yoon Ping, Head of Program, Human Factors in Safety Program, Singapore University of Social Sciences

2) European Maritime Safety Agency (EMSA) 2019 report on “Annual overview of marine casualties and incidents 2019”

3) Maritime & Coastguard Agency Marine Guidance note (MGN 520 M)

4) Oil Companies International Marine Forum (OCIMF) briefing paper October 2020 on “The OCIMF Human Factors Approach – A framework to materially reduce marine risk”.