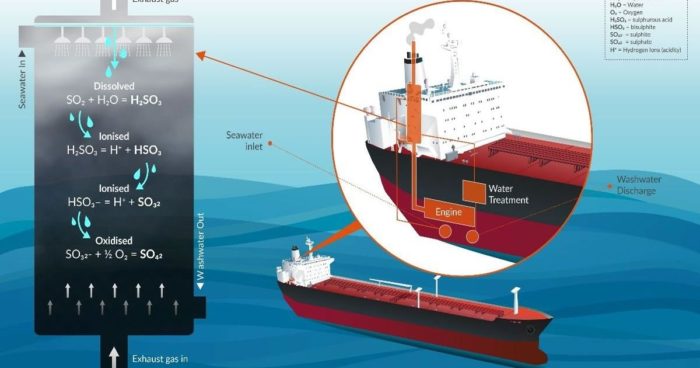

In light of the approaching IMO 2020 sulphur cap, Rivertrace launched a technical white paper that focuses on scrubber technology options and washwater monitoring. The paper provides an insight into the effects of sulphur emissions from ships, the chemistry of scrubbing sulphur from exhaust gases and the benefits associated with scrubber use.

According to the white paper, the options available for shipowners and operators, are:

- Use of fuel with a low sulphur content;

- Use of engine that can run on an alternative;

- Ultra-low sulphur fuel (ULSF) or use a scrubber and continue to burn high sulphur heavy fuel oil (HFO)

Rivertrace, UK-based washwater monitoring system manufacturer, comments that the most crucial challenge to scrubber acceptance is that their technical developments has been completed outside of the IMO’s type approval process. Yet, the manufacturer is of the opinion that the challenge could be overcome by the provision of evidence for scrubber effectiveness.

In addition, the manufacturer alerts shipowners that when selecting scrubber technology, they should pay attention to what washwater monitoring equipment is, to ensure that potential regulatory requirements are met in the future.

Mike Coomber, Managing Director of Rivertrace commented

We have seen recent bans on scrubber operation in some ports because of the washwater discharge issue. However, there is acceptance that the continued use of scrubbers by ships may depend on being able to prove that washwater quality is constantly monitored and shown to meet appropriate standards.

Mr Coomber concluded that overall shipowners should be well-informed when it comes to washwater monitoring equipment options and those used by scrubber manufacturers in order to ensure compliance with future standards.