With the war in Ukraine and China’s zero-Covid policy, delays and prolonged supply bottlenecks are defining this year’s world trade outlook. Yes, demand is softer, notably from China but the backlog is such that supply chains will remain strained for the rest of the year, ING argues.

According to ING analysis, world trade fell by 0.2% in March, with imports from China down 12% and Eastern European CIS countries by 16.4%. With China’s zero-Covid policy continuing throughout April and May, ING doesn’t expect trade data to come in much better in these months.

”Although global schedule reliability, tracked by Sea-Intelligence, improved slightly in February and March, we expect it to have fallen back in April, overall remaining well below 2021 levels.” ING said.

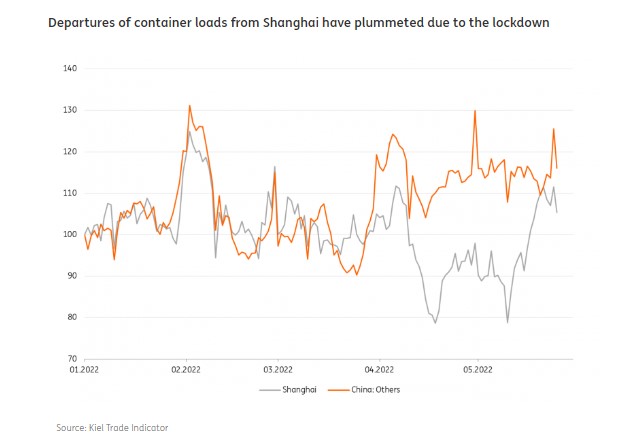

April data should not only capture the effects of the war in Ukraine but also the lockdown in Shanghai, which is having a profound impact on the Chinese economy and on logistics in the country. The container load leaving the port of Shanghai plummeted quite heavily compared to the beginning of the year due to the lockdown, as measured by the Kiel Trade Indicator, as you can see in the chart below. And even if cargoes can be cleared, there are difficulties with inland connections; truck drivers are sometimes being caught in quarantine controls, for instance.

Delays on the import side have mounted, in particular. As manufacturers lift production, a wave of export containers can be expected. Consequently, ING expects the lockdown effects to spill over to other parts of the world in the coming months, although weekly offered transport capacity has been on the rise in the Asia-US shipping route to satisfy still relatively strong demand in the US.

Consequently, shipping rates will remain supported at high levels, with the rise in crude oil prices additionally weighing on transport costs. According to Xeneta, average fuel surcharges alone have been rising by 50% across all trade lines since the beginning of the year due to the rise in crude oil prices.

Furthermore, ING noted the following:

- Material and labour shortages also continue to hinder production and transport. This adds to existing material bottlenecks caused by the pandemic, while sharply increased prices make it difficult for manufacturers to calculate accurately for this year and to commit to prices for delivery to clients much later.

- More than 12% of goods are currently waiting on container ships at port areas globally, up 1.2 percentage points from April, according to the Kiel Trade Indicator, with most of them in China.

- Scarcity continues in the current market environment, which leads to enduring pressures.

- There is still a problem of under-capacity, mostly from the supply side.

- Although weaker consumer demand from China due to dwindling growth expectations and Covid lockdowns, and the EU, due to eroding purchasing power, will alleviate some pressure on supply chains, industrial production is holding up well thanks to high backlogs of work due to shortages which is enough to keep supply chains strained throughout the year.