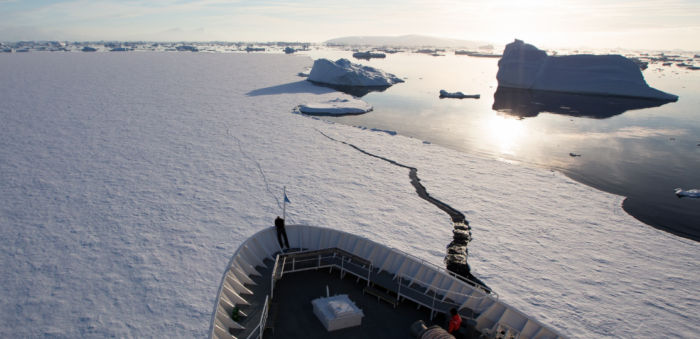

Currently, there is a great boost of shipping activity in the western part of the Northern Sea Route, with ships bringing in materials and equipment for the Yamal LNG plant and the construction of Sabetta port. Many operators eye the passage through NSR, identifying it as a potential international transit route, therefore, a significant expansion of cargo volume is expected over the coming years.

Given that the Arctic remote waters present a number of challenges to ship operators, the Polar Code entered into force on 1st of January 2017, to address important issues in the range of design, construction, equipment, operational, training and environmental protection.

OCIMF has released a paper which outlines the challenges and best practices that operators must consider when passing through NSR. For the safe navigation through the Arctic waters, OCIMF highlights that the type of vessel, operational procedures and personal preparation must be planned in advance. Therefore, a thorough risk assessment for the anticipated conditions of the transit before executing the passage is recommended.

Getting ready for Arctic Trading

In the risk assessment, ship operators need to consider: low temperatures, presence of ice of varying thickness, long polar days and nights, reliability of hydrographic data, lack of infrastructure for oil spill response and Search and Rescue, Polar communications, satellite coverage and winterization requirements.

Considering that ships often deal with restricted visibility when transiting through the NSR, the Polar Code requires, apart from those operating solely in areas with 24 hours of daylight, to be equipped with either two remotely rotatable, narrow-beam searchlights that provide 360o lighting or other means that detect ice.

Taking into consideration many factors, the NSR Administration decides whether the transit requires the use of an icebreaker. Ships occasionally have assistance from nuclear icebreakers, which are more powerful than the conventional icebreakers.

Ships should at all times try to navigate in the channels created by the icebreaker, given that ice massifs – pack ice that cover hundreds of square kilometers – are regularly encountered along the NSR. For that reason, it is advisable ships to evaluate the possibility of taking additional ballast in order to increase draught and prevent damage to the propeller.

Communications in the polar region present particular challenges, OCIMF further notes. It is important that ship to shore communications are maintained throughout the transit and ships under convoy maintain a continuous listening watch on VHF Channel 16. Before the transit begins, a contingency plan should be in place in case the GMDSS systems become unavailable.

Key concerns for safe transfer

For the safe transfer through the pristine polar region, it is recommended to assure the proper operability of ship’s equipment and systems, provide the necessary equipment and supplies and implement procedures for safe operation and personnel welfare. Due to the extremely low temperatures in the arctic region, regular checks should be carried out; therefore, a winterization checklist is vital.

Winterization checklist

Before transiting the NSR, ship operators need to check the following:

- Test of communications equipment

- Test of deck lighting and projectors

- Operational test of navigation equipment

- Operational test of bridge windows heating and clearing systems

- Operational test of horn and whistle heating system

- Operational test of equipment heaters (in steering gear room, control equipment, electric motors, radar scanners, radar gear box)

- Lifeboat and davit readiness

- Deck lines liable to freeze and drained dry

- Sufficient amount of salt, sand and equipment to remove snow and ice is on board for the anticipated voyage

- Firefighting equipment and lifesaving appliances are protected from low temperatures. Potable water normally stored in the lifeboats should be removed and placed in a heated compartment close by unless the lifeboat interior is kept heated.

- Continuous steam supply is available on deck, while ensuring that any deadlegs are drained to prevent freezing.

- Ventilation to interior spaces has been reduced to prevent outside air from coming into direct contact with inside equipment.

- Switch to lower sea chest and operate steam injector if provided.

- When fitted the Pressure Vacuum Breaker (PV Breaker) is checked for correct level of antifreeze and that steam is supplied to the deck water seal.

- Deck hydraulic systems free of water/ moisture.

In 2017, Russia and China agreed to jointly build an ‘Ice Silk Road’ along the NSR as part of the “Belt and Road Initiative“. In 2013, the multi-purpose cargo ship ‘Yong Sheng’, transited the Northern Sea Route. Four years later, the tanker ‘Christophe de Margerie’, world’s first heavy ice-class liquefied natural gas carrier, crossed the same route without an icebreaker escort.

In 2017, Russia and China agreed to jointly build an ‘Ice Silk Road’ along the NSR as part of the “Belt and Road Initiative“. In 2013, the multi-purpose cargo ship ‘Yong Sheng’, transited the Northern Sea Route. Four years later, the tanker ‘Christophe de Margerie’, world’s first heavy ice-class liquefied natural gas carrier, crossed the same route without an icebreaker escort.