In its latest Safety Digest report, the UK MAIB provides valuable lessons learned after a second engineer onboard a chemical/ products tanker was badly scalded while carrying out a routine external inspection of the vessel’s main engine.

The incident

The vessel was alongside and engaged in cargo operations at the time and the second engineer was being assisted by a third engineer. During the course of the inspection, the second engineer stepped off the walkway and squeezed between two cylinder head covers.

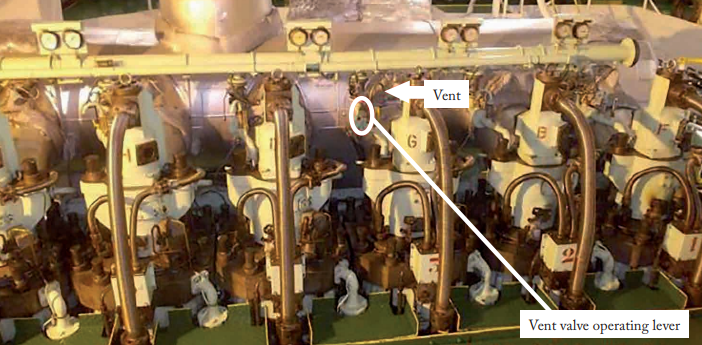

As he did so, his boiler suit pocket became snagged on the operating lever of a jacket water vent valve. As the lever moved, the valve opened and pressurised water, at 75ºC, was released through the vent and sprayed over the second engineer.

The confined location prevented the second engineer’s escape, but the swift actions of the third engineer, who managed to close the valve, saved him from further scalding injuries.

Following the accident, the company took immediate action to remove the vent valve operating levers on all its vessels with similar engines. This was a temporary measure until proper securing or blanking arrangements could be put in place.

Lessons learned

- Single valve isolation of a pressurised hot water system, with an open-ended connection, is an incident waiting to happen, particularly in a vibration-heavy environment. In such circumstances, the open ended pipes or valves should be plugged or blanked off.

- Lever-operated ball valves and cocks are susceptible to inadvertent operation and should be installed in such a way that the operating lever does not protrude into walkways or working areas.

- It is always good practice to install lever-operated ball valves that can easily be locked in both the open and closed positions.