In its latest Safety Digest, UK MAIB provides lessons learned from an incident where a transfer vessel made heavy contact with a landing platform resulting in a bow indentation and buckling damage to the hull plating.

The incident

A passenger transfer vessel was approaching a wind farm turbine with three crew and three windfarm technicians on board. It was the first trip of the day and weather conditions were favorable with good visibility, a light breeze and gentle sea. The vessel propulsion system’s landing mode gave the skipper precise manoeuvring control when approaching wind turbines to embark or disembark passengers.

As the vessel approached the turbine’s landing platform, the skipper reduced speed and selected the landing mode in preparation for the technicians’ transfer. The skipper moved the propulsion control lever to astern to further reduce speed. However, the vessel did not respond as expected and so he increased the lever fully astern. This had no effect and the transfer vessel made heavy contact with the landing platform.

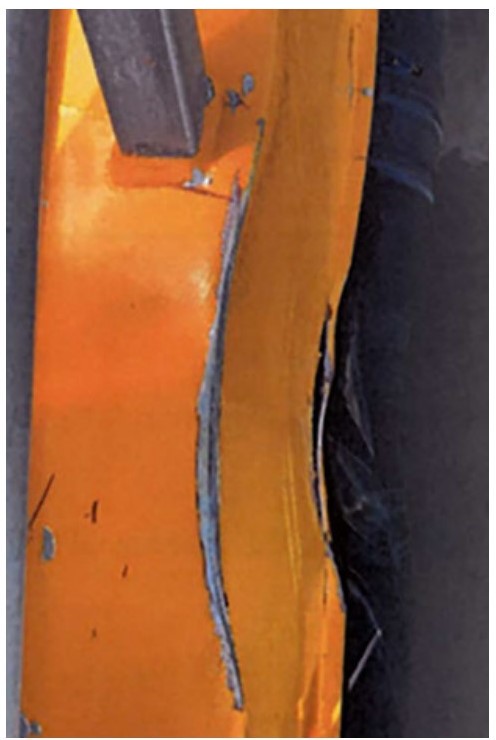

The impact caused a bow indentation and buckling damage to the hull plating. One of the technicians was injured when he was thrown against the table in front of his seat; he was treated by ambulance paramedics when the vessel returned to harbour.

transfer vessel’s bow area / Credits: UK MAIB

Lessons learned

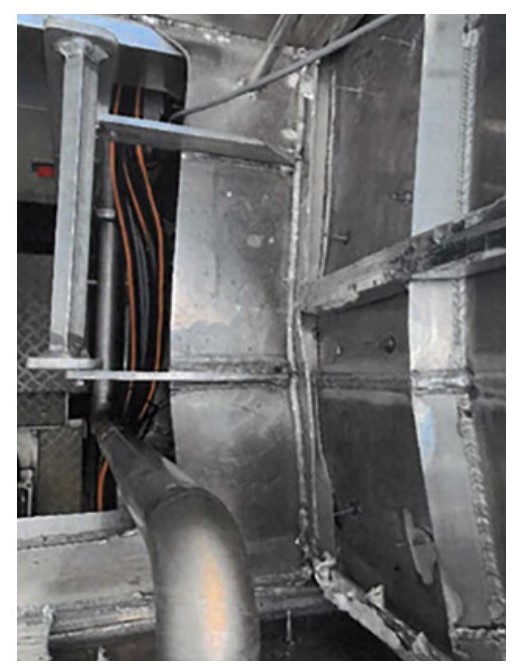

#1 Risk: A post-accident technical analysis identified that the loss of propulsion control resulted from a seizure of the mechanical arm controlling propeller pitch. This occurred because the installation arrangement resulted in excessive wear, with a consequent risk of the pitch control arm locking when in use; something that the manufacturer was able to replicate in post-accident trials. Although not the cause of the accident, technical analysis found excessive water ingress in an electrical terminal box on the propulsion control system.

(unrelated to the propulsion control loss) / Credits: UK MAIB

It was further established that the water ingress was caused by previous maintenance to an adjacent seawater cooler, when residual water had been allowed to drain over the electrical control box. Since the accident, the company has taken action to improve the installation arrangements of the propeller pitch control system and relocated the seawater cooler.

#2 Communicate: It is important to keep passengers informed if things are going wrong. Although this accident was hard to prevent, post-event CCTV analysis indicated that there was about 10 seconds between the skipper realizing that control was lost and the impact. This is a very short timeframe in which to deliver an emergency response; however, taking any opportunity to warn passengers and call for them to ‘brace’ would potentially reduce the risk of injury.

#3 Maintain: Take care with maintenance and repairs. The residual water that drained away during the seawater cooler maintenance should have been prevented from flowing over electrical components. Taking time to protect other equipment from damage during maintenance tasks will prevent damage and future breakdowns.

#4 Check: Always check the propulsion manoeuvring control response. The vessel was on its first trip of the day out to the wind farm. At the end of the passage, and before the precise manoeuvring, a full function check of all propulsion modes, including ‘testing the brakes’ by going astern, may have detected the problem in advance of the heavy contact.