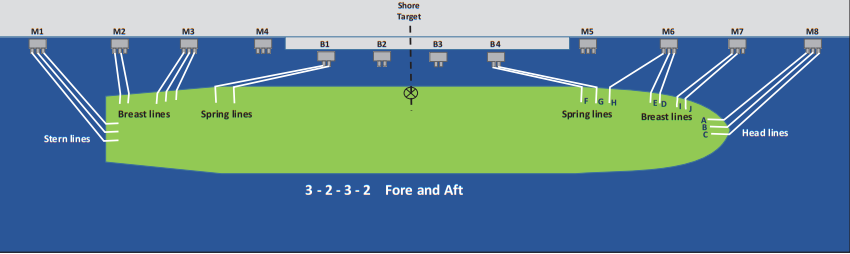

A large LNG carrier was docked in an LNG terminal in UK. The 345.30m LOA carrier was moored with a total number of 20 lines (high modulus polyethylene ropes) following the ‘3-2-3-2 fore and aft’ rule. The vessel had 22 lines on board (as per manufacturer’s requirements) to be used during mooring operations of 44mm diameter Steelite Superline Xtra high modulus polyethylene (HMPE) with a specified minimum breaking load (MBL) of 137t.

While vessel was moored, a line parted and injured 3rd Officer who suffered severe injuries. When the line parted the wind was westerly at about 32kts and the tidal stream was ebbing to the west at 0.6kt (the tidal range was 4m). The air temperature was about 6°C, it was raining and it was dark. These conditions were similar to those predicted in the local inshore weather forecasts. The prevailing wind was reaching max strength with extended gusts. One of the fore spring lines parted due to tensile overload even though the load being applied to the line at the time was less than a quarter of its specified minimum breaking load.

But how did an inspected mooring rope part despite the monitoring and inspections of same as per Company’s requirements? All mooring lines had been subjected to regular visual inspections by the ship’s crew and the rope manufacturer’s representatives, and their condition had always been assessed to be good. The PMS required 4-monthly inspections of each rope. To do this, the ropes were removed from the winch drums and visually inspected over their entire length. The PMS provided information on types of damage to look for and guidance on rope rejection or discard criteria.

In order to prolong the life of the mooring ropes, the PMS recommended that:

- Ropes normally used as ‘Springs’ should be rotated with other ropes every 2 years; and,

- All ropes should be end-for-ended every 4 years.

The maintenance undertaken and observations made during the rope inspections were recorded in the vessel’s electronic PMS database. In addition, records were maintained of the air temperatures and wind speeds at the terminals while the vessel was moored.

Jacked rope construction

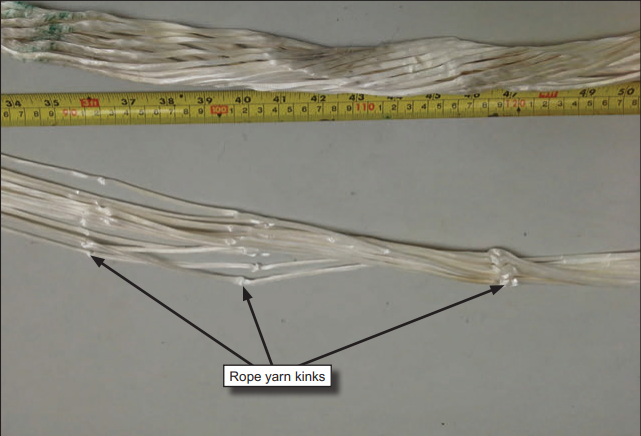

Accordingly, the main issue with such rope inspection is that jacketed design prevented the identification of key discard criteria such as broken yarns and fused fibres. In addition, other high modulus synthetic fibre rope condition degradation phenomena, such as creep, cannot readily be assessed without physically dissecting the rope.

[smlsubform prepend=”GET THE SAFETY4SEA IN YOUR INBOX!” showname=false emailtxt=”” emailholder=”Enter your email address” showsubmit=true submittxt=”Submit” jsthanks=false thankyou=”Thank you for subscribing to our mailing list”]

So were these ropes adequate for use on board such vessel in respect of size and operational envelop? As the official investigation concluded, the arrangement of mooring decks on board contributed significantly to the rope’s loss of strength and the officer being injured; the mooring lines used on board vessel (and similar vessels in the same fleet) were not suitable for the application; and the primary influences on rope degradation and failure modes were not fully understood by the user.

Close visual examination of the break site identified that the yarn fibres had suffered localised fusing and hardening, and that the failure had been caused by tensile overload. Away from the break site, the rope appeared to be in generally good condition.

Key feedback

A technical Company authorized to provide failure analysis based on broken line samples. The outcome of this analysis after investigation and laboratory measurements was that the inner part of jacked rope (3-strands) reveled yarn kinks which were effective to failure.

Based on the results of break load tests, and taking the number of failed yarns discovered in damaged rope into account, the authorized Company estimated that the residual strength of the rope samples tested could have been as low as 61.6t. This was about 45% of its specified MBL (137t).

Additionally, the painting of snap back areas had also contributed to the accident. As per previous Best Practice Guidance, areas near mooring points should be marked for the Snap-Back hazard.

However, this practice created a false sense of safety in case the seafarer was not on or next to yellow marked area. Considering that the reaction of a broken line under tension practically is unknown and difficult to be predicted, such marking of “danger areas” is not actually a safety practice.

Lessons learned

Consequently, this incident and several other similar led to the revision of some of the mooring practices:

- The OCIMF Guidance for Mooring was revised to MEG-4 in order to address similar issues; new definitions were introduced and new guidance was provided in respect of purchasing, using, inspecting and retiring mooring lines.

- The practice regarding snap back zones was also revised; the markings on the deck were removed and replaced with the generic warning that all mooring decks are subject to snap-back hazard (Image 4)

- Effective procedures are now required to be inforce on board vessels in order to minimize incidents during mooring operations. A comprehensive and detailed risk assessment should be undertaken prior conducting such operations.

- An effective tool box meeting is to be conducted also in order to provide guidance on the established mooring plan taking into consideration: Vessel’s arrangements and equipment; Terminal or port arrangements and ; Prevailing and predicted environmental conditions

- Lastly, all mooring stations should be under the control and monitoring of a competent officer who should use a Stop work procedure or authorization in order to protect fellow seafarers and vessel’s equipment from unpleasant situations during mooring.