ABS hosted its 2nd Ballast Water Management Workshop in Houston, where over 20 representatives from 13 shipping companies were invited to participate and share their experiences with the challenges of the BWMS newbuilding and retrofit process, after completing a comprehensive questionnaire that covered key aspects of selecting, installing and operating a BWMS. This 2019 comprehensive best practices report consolidates input and feedback gathered from all the workshops and aims to capture key discussion topics, lessons learned, and insight shared by the workshop attendees on the installation and operation of BWM systems.

The key factors that provide successful and compliant BWMS operations are installation considerations, crew training, commissioning, operations, and maintenance and repair.

The participants of the workshop discussed the best practices for a smooth BWMS integration and operation. In the meantime, they shared their post-operational experiences and lessons learned when addressing BWMS retrofit problems.

The best practices include:

- The importance of advance planning including creating detailed timelines that anticipate delays to help mitigate cost impacts for BWMS retrofits;

- Incorporating ship-specific contingency measures into the BWM Plan (BWMP) to avoid inservice downtime and financial penalties;

- System-specific training for shoreside support and ship crew is critical for effectively operating and maintaining the BWMS;

- Monitoring data and operational trends to better understand system design limitations (SDL) can help the crew predict the challenges of the vessel’s planned operational routes;

- Working with the vendor after-sales global support is important to achieve uninterrupted system operations.

The discussions and the participants’ comments presented some growing concerns among the shipowners and operators across the globe. These include:

- Operational reliability of the systems that could result in a non-compliance leading to financial penalties, port state detentions or commercial losses;

Some common problems identified are:

Fluctuating and unstable TRO sensor and monitor readings that are sensitive to environmental conditions. These are used for active-substance-based BWMS to control the chemical dosing during treatment (some makes) and control neutralization chemical injection during de-ballasting to reduce the total residual oxidant (TRO) for compliance with local regulations.

Frequent outages and replacement of UV lamps and clogging of filters that require frequent or continuous back-flushing operations (particularly in high turbidity water conditions causing reduced throughput from the ballast pumps.

Inability to operate EC-based BWMS in freshwater or low salinity water conditions, requiring alternative arrangements to carry salt water or brine solutions to achieve the minimum salinity requirements for the BWMS feed water, Predicting low UV transmittance challenges (affecting all UV-based BWMS) caused by weather (seasonal) or other variables (i.e., shipping density or dredging operations, etc.).

- No single treatment technology works for all vessels. In other words, there is no single BWM treatment technology that meets the demands and operational needs for all types of vessels. The selection of the most suitable BWMS depends on several factors:

- Vessel configuration, ballast capacity and pump sizes;

- Trade routes and operating profiles;

- Differences between high and low ballast dependent vessels (i.e., retention times);

- Ability of the BWMS to support gravity ballasting or de-ballasting operations;

- Ballast water treated rated capacities (TRC);

- Available installation spaces and excess power capacity;

- Equipment installation and design issues when integrated with the vessel’s existing machinery and piping systems.

According to the report, an improper BWMS option could affect the commercial operations of the vessel and could result in loss of charter opportunities. In the worst-case scenario, the wrong BWMS selection might require a second BWMS retrofit to provide compliance. That mistake might not be economically viable for an existing vessel leading to early scrapping of the vessel.

- Vendor technical support network and after-sales service. The participants indicated inconsistent after-sales support between different BWMS vendors. Limited global availability of vendor’s technical attendance caused prolonged system outages. Also, they commented that delayed responses to their service requests and delayed technical assistance caused problems with charter opportunities.

- Quality of the software and hardware systems. The participants mentioned control system software faults and hardware failures that caused unexplained alarms interrupting

continuous operations of the BWMS affecting cargo operations. Some of them were unable to verify the authenticity of the control software or that the software updates and upgrades for the installed BWMS met USCG or IMO approvals. - Effective crew training and competency levels. The attendees indicated effective crew training to allow proper operations, maintenance, troubleshooting, and repairs was problematic. The transfer of experience with the selected BWM technology from one crew to another is challenging. Experienced crew trained on a specific BWMS may not be able to apply their experience or knowledge effectively when working on another vessel employing a different BWM technology.

- Operation, Maintenance, and Safety Manual. The results indicated differences between BWMS Operation, Maintenance, and Safety Manuals (OMSM). According to discussions, some OMSMs are less useful than others. Some owners reported routine maintenance and troubleshooting are not always well defined. Differences in installed configurations were not always adequately explained in the manuals.

The participants reported that some OMSMs were either too complicated (operators could not easily figure out the vendor’s instructions) or were too generic (not ship-specific enough).

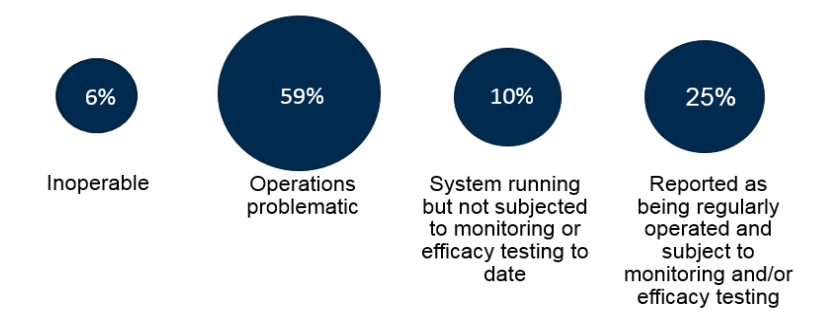

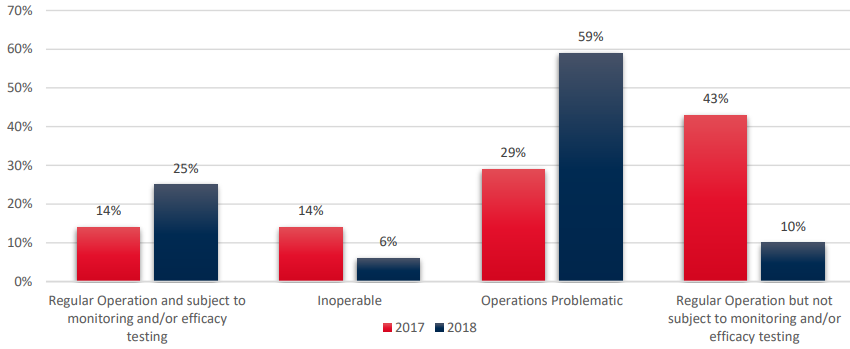

In addition, ABS proceeded to comparing 2017 vs. 2018 BWMS Operational Experience Survey Results.

Concluding, the 2018 questionnaire results from 483 BWMS installations more than doubled the number from the 2017 surveys where a total of 220 BWMS installation questionnaires were received.

For more information click on the PDF herebelow